24

Greasing the Bearings

The cutting unit must be lubricated regularly; refer to the

Recommended Maintenance Schedule, page 19. Grease

with No. 2 general purpose lithium base or molybdenum

base grease.

1. Stop the engine, set the parking brake, remove the key,

and disconnect the spark plug wire(s) from the spark

plug(s).

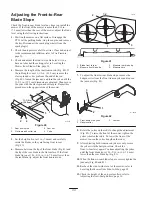

2. Grease the fittings on the three spindle bearings

(Fig. 25).

3. Grease the idler pulley pivot (Fig. 25).

m–5157

Figure 25

Top View

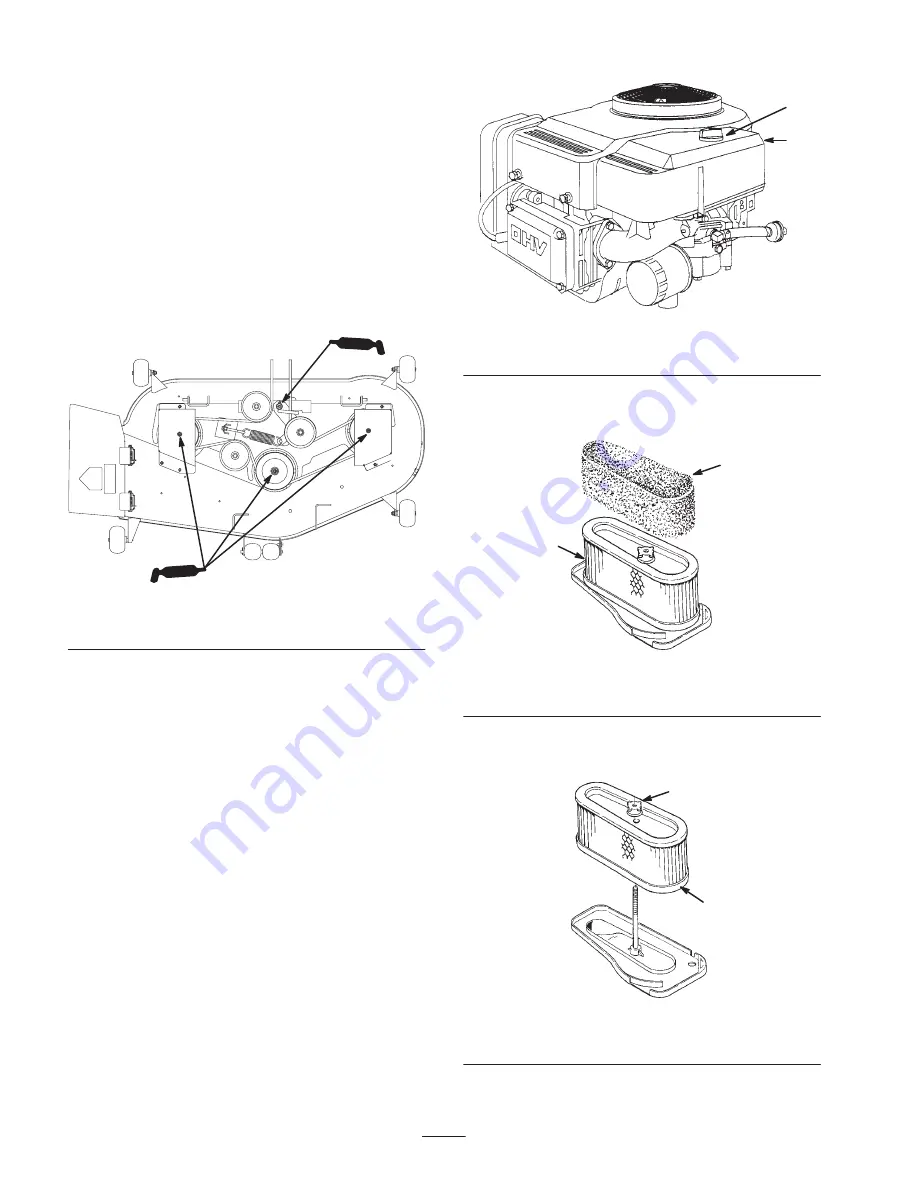

Air Cleaner

Service Interval/Specification

Foam Element: Clean and oil after every 25 operating

hours, or yearly, whichever occurs first.

Paper Element: Replace after every 100 operating hours, or

yearly, whichever occurs first.

Note: Service the air cleaner more frequently (every few

hours) if operating conditions are extremely dusty or sandy.

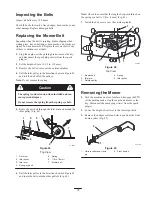

Removing the Foam and Paper Elements

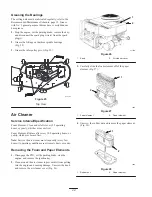

1. Disengage the PTO, set the parking brake, stop the

engine, and remove the ignition key.

2. Clean around the air cleaner to prevent dirt from getting

into the engine and causing damage. Unscrew the knob

and remove the air cleaner cover (Fig. 26).

1

m–1798

2

Figure 26

1.

Knob

2.

Air cleaner cover

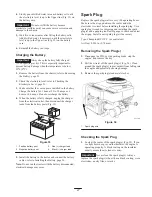

3. Carefully slide the foam element off of the paper

element (Fig. 27).

1

2

1864

Figure 27

1.

Foam element

2.

Paper element

4. Unscrew the rubber nut and remove the paper element

(Fig. 28).

2

1

1865

Figure 28

1.

Rubber nut

2.

Paper element

Summary of Contents for Z16-44 TimeCutter

Page 6: ...6 ...

Page 7: ...7 Slope Chart ...

Page 8: ...8 ...

Page 11: ...11 104 8014 1 Parking brake 104 5091 104 8088 ...

Page 38: ...38 ...

Page 39: ...39 ...