Service Dealer’s Guide to Great Quality of Cut

4 - 13

Checking and Adjusting the Blade Level

4.

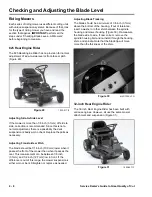

To adjust the front-to-rear pitch, loosen the front

pivot plate mounting bolts slightly (Figure 44).

Figure 44

XL38pit2.TIF

5.

Rotate lock nuts on eyebolts to change the

adjustment. To raise the front of the mower,

tighten the eyebolt lock nuts. To lower the front of

the mower, loosen the eyebolt lock nuts.

6.

After adjusting both eyebolt lock nuts evenly,

check the front-to-rear pitch again. Continue

adjusting until the blade pitch is within

specification.

7.

Tighten the pivot plate mounting bolts.

8.

Recheck the side-to-side level and correct if

necessary (see “Adjusting Side-to-Side Level—All

Cutting Units” on page 4-10).

9.

Once the front-to-rear pitch and side-to-side level

are within specification, continue by checking and

adjusting the blade tracking (see “Adjusting Blade

Tracking” on page 4-14).

44-inch (111.7cm) Cutting Unit

1.

Check side-to-side level and adjust as needed

(see “Adjusting Side-to-Side Level—All Cutting

Units” on page 4-10).

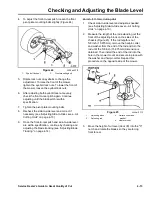

2.

Measure the length of the rod extending out the

front of the adjusting block on the sides of the

chassis (Figure 45). If the rod length is not

5/8 inch (15.875mm), remove the hairpin cotter

and washer from the end of the rod and turn the

rod until the 5/8 inch (15.875mm) dimension is

obtained. Then install the end of the rod into the

hole in the mower mount and secure in place with

the washer and hairpin cotter. Repeat this

procedure on the opposite side of the mower.

Figure 45

XL44pit1.TIF

3.

Move the height of cut lever (deck lift) into the "C"

notch and rotate the blades so they are facing

front to rear.

1.

Eye bolt locknut

2.

Pivot mounting bolt

1.

Adjusting block

2.

Adjusting rod

3. Hairpin cotter and

washer

4. Mower mount

Summary of Contents for Recycler 20351

Page 1: ...MANUAL ...

Page 6: ...iv Service Dealer s Guide to Great Quality of Cut This page intentionally left blank ...

Page 8: ...1 2 Service Dealer s Guide to Great Quality of Cut This page intentionally left blank ...

Page 12: ...2 4 Service Dealer s Guide to Great Quality of Cut This page intentionally left blank ...

Page 16: ...3 4 Service Dealer s Guide to Great Quality of Cut This page intentionally left blank ...

Page 40: ...4 24 Service Dealer s Guide to Great Quality of Cut This page intentionally left blank ...

Page 44: ...5 4 Service Dealer s Guide to Great Quality of Cut This page intentionally left blank ...

Page 56: ...7 10 Service Dealer s Guide to Great Quality of Cut This page intentionally left blank ...