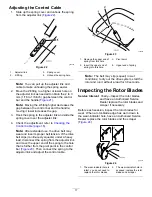

g008238

Figure 31

1.

Drive-belt cover

6.

Drive belt

2.

Bolt (3)

7.

Rotor shaft

3.

Rotor-pulley bolt

8.

Brake spring (unhook from

idler arm here)

4.

Curved washer

9.

Idler pulley

5.

Rotor pulley

10.

Engine pulley

2.

Unhook the brake spring from the idler arm to

release the belt tension (

).

3.

Remove the screw and curved washer that

holds the rotor pulley (

).

4.

Remove the rotor pulley and the drive belt

(

).

5.

Install the new drive belt, routing it as shown in

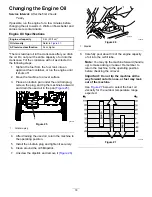

g008317

Figure 32

1.

Brake spring (install on

idler arm here)

3.

Engine pulley

2.

Idler pulley

4.

Rotor pulley

Note:

Route the new drive belt first around the

engine pulley, then the idler pulley, and finally

around the loose rotor pulley positioned just

above the rotor shaft (

).

6.

Install the rotor pulley onto the rotor shaft (

7.

Install the curved washer and the rotor-pulley

bolt and tighten them securely (

Note:

The concave side of the curved washer

goes against the outside of the pulley.

8.

Install the brake spring onto the idler arm (

9.

Install the drive-belt cover with the bolts that you

removed in step

Note:

Ensure that the drive belt is properly

adjusted and operating; refer to

Control Cable (page 16)

and

Control Cable (page 17)

.

Adjusting the Quick Shoot

Control

Model 38756

If there is more than 13 mm (1/2 inch) of slack in the

Quick Shoot cable (

) or the discharge chute

does not rotate left and right in equal angles, adjust

the Quick Shoot control cables.

g006514

Figure 33

1.

13 mm (1/2 inch) maximum slack

1.

Loosen the 2 Quick Shoot control-cable clamps

(

).

g286559

Figure 34

1.

Cable clamps

20

Summary of Contents for Power Clear 721

Page 24: ......