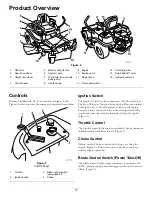

Safety and Instructional

Decals

Safety decals and instructions are easily visible to the operator and are located near any area of potential

danger. Replace any decal that is damaged or lost.

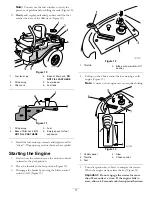

93-7009

1.

Warning—don't operate the mower with the deflector up or

removed; keep the deflector in place.

2.

Cutting/dismemberment hazard of hand or foot, mower

blade—stay away from moving parts.

99-3943

1.

Engine

106-8717

1.

Read the instructions before servicing or performing

maintenance.

2.

Check tire pressure every 25 operating hours.

3.

Grease every 25 operating hours.

4.

Engine

110-6691

1.

Thrown object hazard—keep bystanders a safe distance

from the machine.

2.

Thrown object hazard, mower—do not operate without the

deflector, discharge cover, or grass collection system in

place.

3.

Cutting/dismemberment of hand or foot—stay away from

moving parts.

112-9840

1.

Read the

Operator's

Manual

.

3.

Remove the ignition key

and read the instructions

before servicing or

performing maintenance.

2.

Height of cut

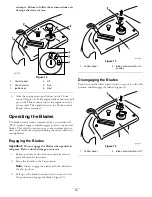

114-1606

1.

Entanglement hazard, belt—keep all guards in place.

8

Summary of Contents for 74395

Page 10: ...119 8874 1 Low speed 2 High speed 10 ...

Page 50: ...Schematics g017655 Electrical Diagram Rev A 50 ...

Page 51: ...Notes 51 ...