Figure 13

1.

Hydraulic tank cap

4.

Remove the dipstick from the filler neck and wipe it

with a clean rag. Insert the dipstick into the filler neck;

then remove it and check the fluid level. The fluid level

should be between the 2 marks on the dipstick.

5.

If the level is low, add the appropriate fluid to raise the

level to the upper mark.

6.

Install the dipstick and cap onto the filler neck.

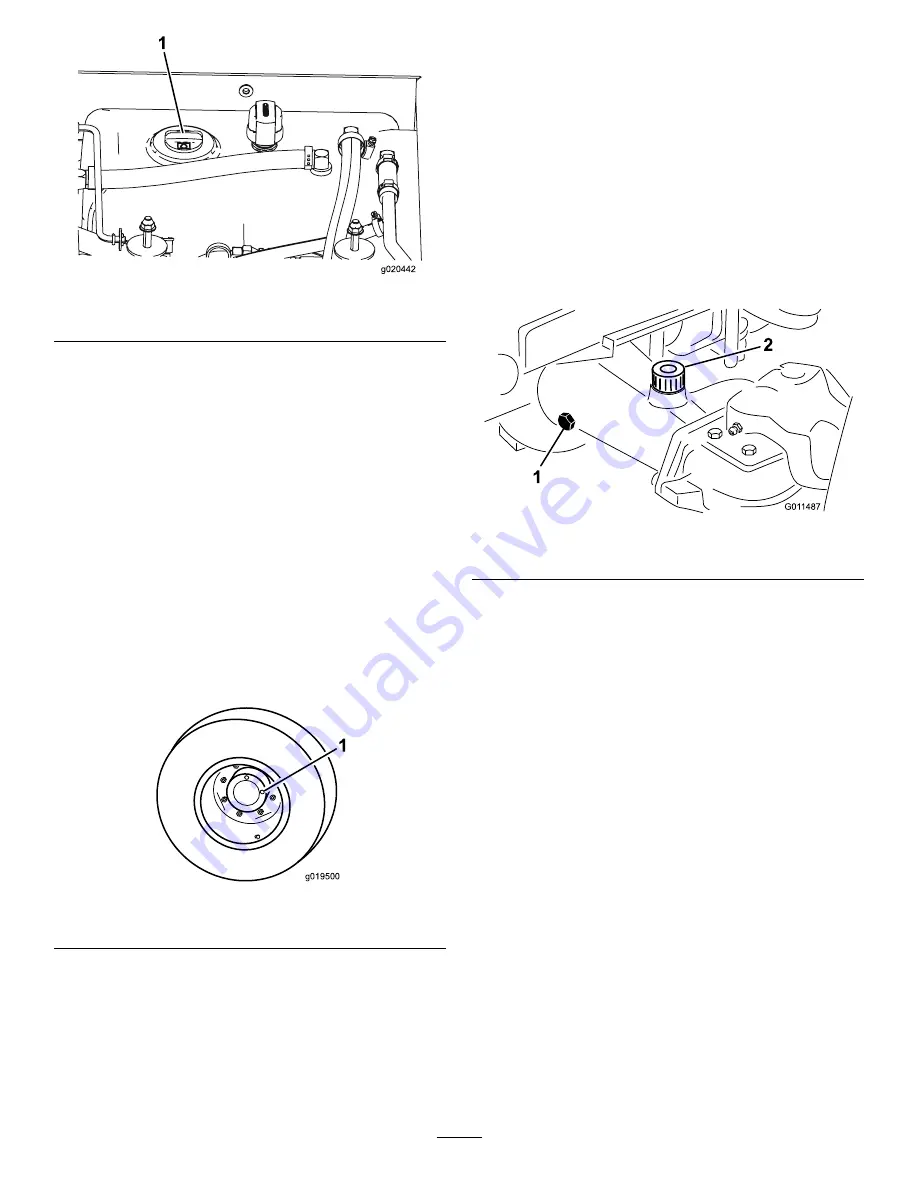

Checking the Planetary Gear Drive Oil

Service Interval:

Every 400 hours

Check the oil level after every 400 hours of operation or if

external leakage is noted. Use high quality SAE 85W-140 gear

lube as a replacement.

1.

With machine on level surface, position the wheel so

one check plug (

) is at the 12 o'clock position

and the other is at 3 o'clock position.

g019500

Figure 14

1.

Check/drain plug (2)

2.

Remove the plug at the 3 o’clock position (

Oil level should be at the bottom of the check plug

hole.

3.

If the oil level is low, remove the plug at the 12 o’clock

position and add oil until it begins to flow out of the

hole at the 3 o’clock position.

4.

Install both plugs.

Checking the Rear Axle Lubricant

Service Interval:

Every 400 hours

The rear axle is filled with SAE 85W-140 gear lube. Check the

oil level before the engine is first started and every 400 hours

thereafter. The capacity is 2.4 L (80 oz). Visually inspect for

leaks daily.

1.

Position the machine on a level surface.

2.

Remove a check plug from one end of the axle (

) and make sure that the lubricant is up to the bottom

of the hole. If the level is low, remove the fill plug

(

) and add enough lubricant to bring the level

up to the bottom of the check plug holes.

Figure 15

1.

Check plug

2.

Fill plug

Checking the Rear Axle Gear Box

Lubricant

Service Interval:

Every 400 hours

The gear box is filled with SAE 85W-140 gear lube. Check the

oil level before the engine is first started and every 400 hours

thereafter. The capacity is 0.5 L (16 oz). Visually inspect for

leaks daily.

1.

Position the machine on a level surface.

2.

Remove the check/fill plug from the left side of the

gear box (

) and make sure that lubricant is

up to the bottom of the hole. If the level is low, add

enough lubricant to bring the level up to the bottom

of the hole.

27