27

1

2

3

4

4

m–6510

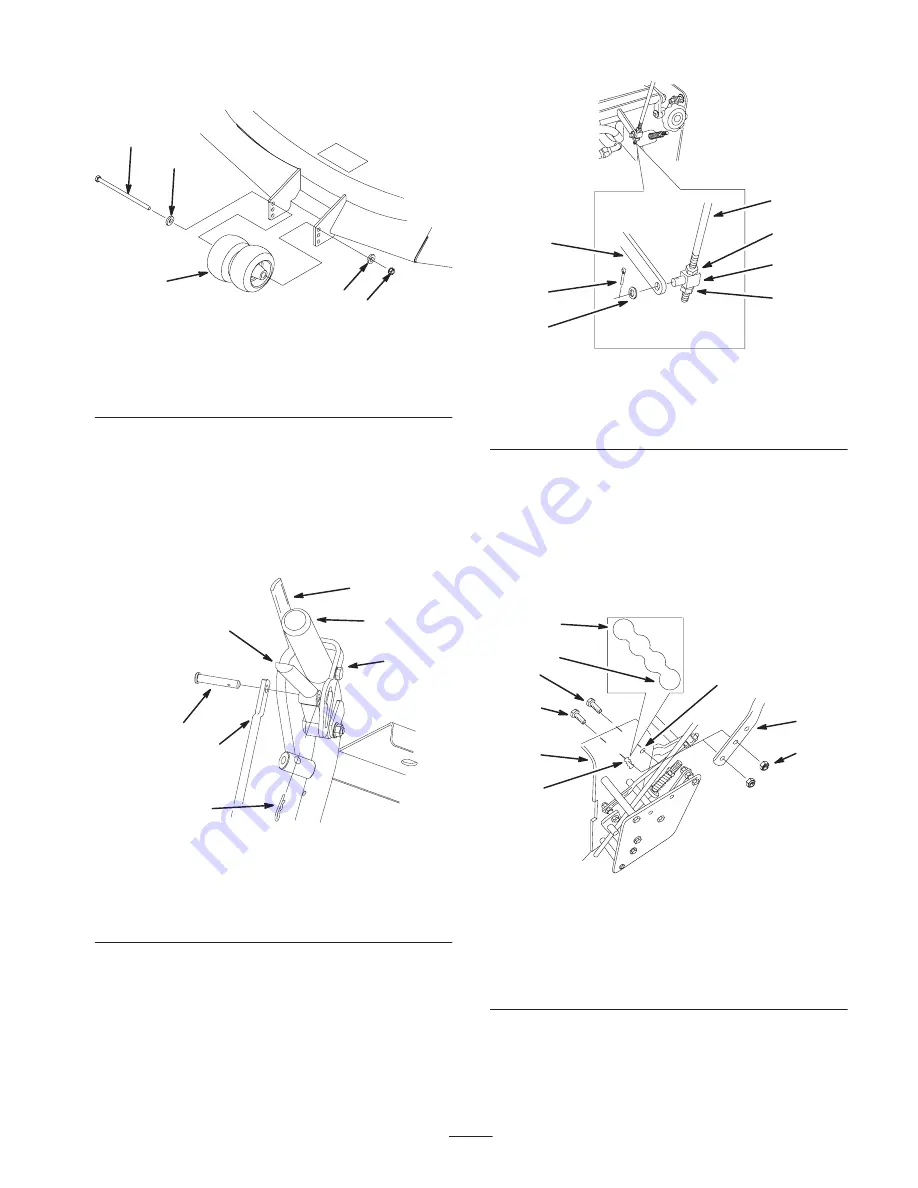

Figure 22

1.

Center Gage Wheels and

Spacer

2.

Nut

3.

Bolt

4.

Washer

Adjusting the Handle Height

The handle position can be adjusted to match the

operator ’s height preference.

1. Remove the hairpin cotter pin and clevis pin from the

drive lever and neutral lock (Fig. 23).

m–6639

6

5

3

7

2

4

1

Figure 23

1.

Left handle shown

2.

Neutral lock

3.

Clevis pin

4.

Drive lever

5.

Control rod

6.

Operator Presence

Control lever (OPC)

7.

Hairpin cotter

2. Loosen the nuts holding the swivel connected to the

speed control crank (Fig. 24).

m–6602

1

2

3

4

5

3

6

Figure 24

1.

Speed control rod

2.

Swivel

3.

Nut

4.

Speed control crank

5.

Cotter pin

6.

Washer

3. Loosen the upper flange bolts (3/8 x 1 inch) and flange

nut securing handle to rear frame (Fig. 25).

4. Remove the lower flange bolts (3/8 x 1 inch) and

flange nuts securing handle to rear frame (Fig. 25).

5. Pivot handle to desired operating position and install

lower flange bolts (3/8 x 1 inch) and flange nuts into

mounting holes. Tighten all flange bolts.

m–6600

7

8

9

2

1

3

5

6

4

Figure 25

1.

Handle assembly

2.

Rear frame

3.

Flange nut, 3/8 inch

4.

Flange bolt, 3/8 x 1 inch

5.

Upper mounting hole

6.

Lower mounting holes

7.

Low position

8.

High position

9.

Flange bolt, 3/8 x

1–1/4 inch

6. Adjust the swivel on the speed control rod and tighten

the nuts against the swivel (Fig. 24).

Summary of Contents for 30436

Page 7: ...7 Slope Chart...

Page 8: ...8...