30

m–6367

Figure 33

Lubricate the Transmission and Idler

Bracket

1. Lubricate the transmission couplers located in the back

of the machine (Fig. 34).

m–6594

Figure 34

Greasing the PTO Drive Belt Idler

1. Stop the engine, chock or block tires, remove the key

and disconnect the spark plug wire(s) from the spark

plug(s).

2. Grease the idler pulley pivot for the deck (Fig. 35).

m–5196

Figure 35

Cleaning the Cooling System

Service Interval/Specification

Before each use, check and clean engine cooling system.

Remove any build–up of grass, dirt or other debris from the

cylinder and cylinder head cooling fins, air intake screen on

flywheel end, and carburetor–governor levers and linkage.

This will help insure adequate cooling and correct engine

speed and will reduce the possibility of overheating and

mechanical damage to the engine.

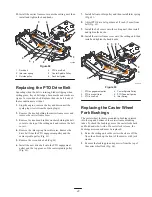

Checking the Tire Pressure

Service Interval/Specification

Maintain the air pressure in the front and rear tires as

specified. Check the pressure at the valve stem after every

40 operating hours or monthly, whichever occurs first

(Fig. 36). Check the tires when they are cold to get the most

accurate pressure reading.

Rear Tire Pressure: 12–14 psi (83–97 kPa)

Caster Tire Pressure: 25–30 psi (172–207 kPa)

Summary of Contents for 30432

Page 6: ...6...

Page 7: ...7 Slope Chart...

Page 8: ...8...

Page 10: ...10 104 8186 104 8569 105 4111 105 4146 106 5532 106 0699 106 5511 106 0635...