31

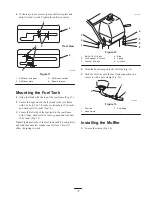

5. Install air intake screen, recoil starter and fan housing.

3

2

4

1

m–7450

5

Figure 38

1.

Air intake screen

2.

Fan housing

3.

Recoil starter

4.

Bolt

5.

Nut

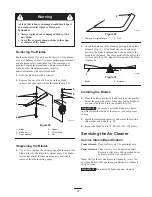

Checking the Tire Pressure

Service Interval/Specification

Maintain the air pressure in the front and rear tires as

specified. Check the pressure at the valve stem after every

50 operating hours or monthly, whichever occurs first

(Fig. 39). Check the tires when they are cold to get the most

accurate pressure reading.

Pressure: 15 psi (103 kPa) rear tires

25–30 psi (172–207 kPa) caster tires

1

Figure 39

1.

Valve stem

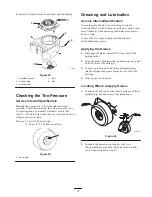

Greasing and Lubrication

Service Interval/Specification

Grease the areas shown at the intervals given in the

Locating Where to Add Grease section below. Grease them

more frequently when operating conditions are extremely

dusty or sandy.

Grease with No. 2 general-purpose lithium-base or

molybdenum-base grease.

Applying the Grease

1. Disengage the blade control (PTO) lever and set the

parking brakes.

2. Clean the grease fittings with a rag and scrape any paint

from the front of the fitting(s).

3. Connect a grease gun to the fitting and pump grease

into the fittings until grease begins to ooze out of the

bearings.

4. Wipe up any excess grease.

Locating Where to Apply Grease

1. Lubricate the drive and caster wheel bearings and front

spindles (Fig. 40) after every 8 operating hours.

m–3780

Figure 40

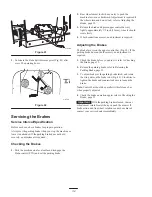

2. Lubricate the transmission couplers after every

100 operating hours and the idler bracket pivots after

every 8 operating hours (Fig 41).