Hydraulic System

Maintenance

Replacing the Hydraulic Filter

Service Interval:

Every 200 hours

1. Position machine on a level surface.

2. Lower the boom and set the parking brake.

3. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

4. Remove the top cover.

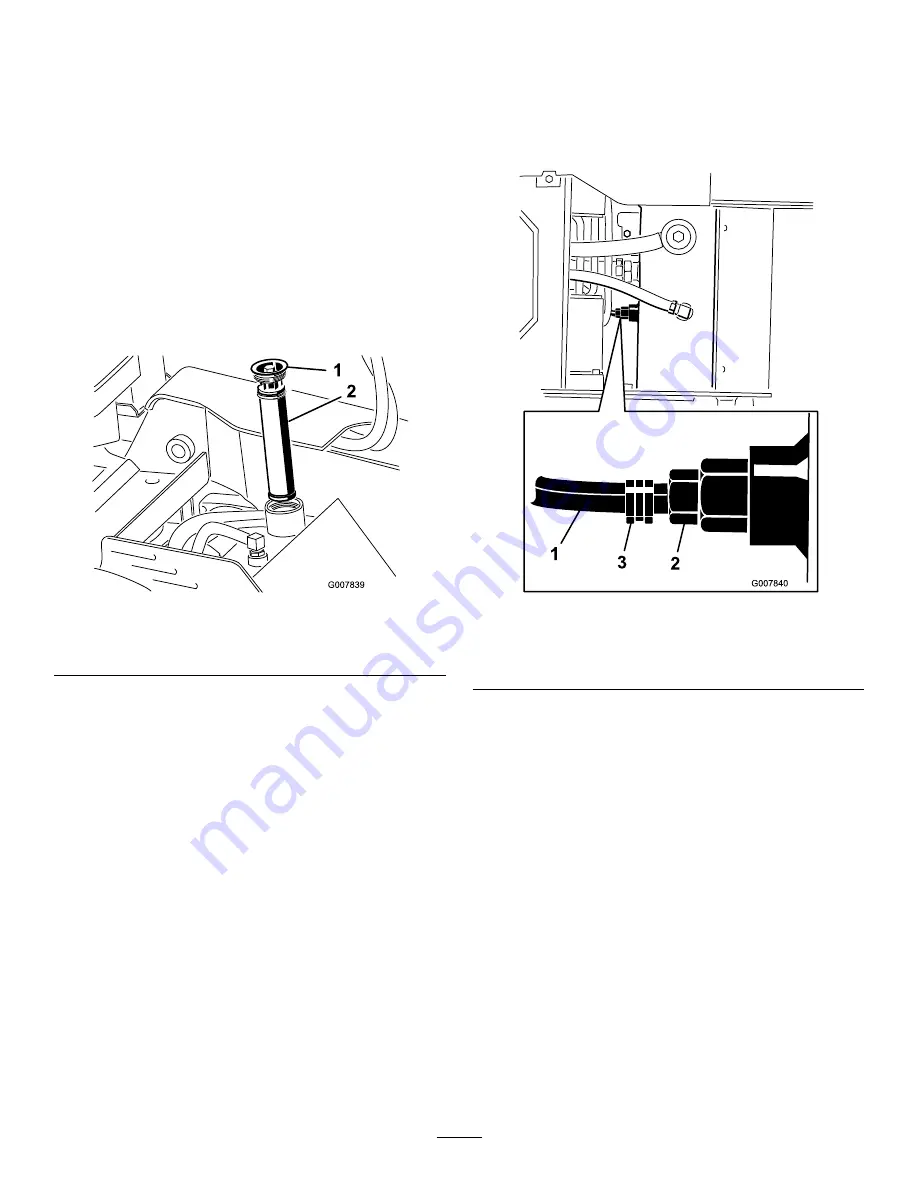

5. Remove and discard the old filter (Figure 57).

Figure 57

1.

Filler cap

2.

Hydraulic filter

6. Install the replacement hydraulic filter and filler cap

(Figure 57) and torque bolt on top to 110 to 140

in-lb (13 to 15.5 N-m).

7. Clean up any spilled fluid.

8. Install the top cover.

Changing the Hydraulic Fluid

Service Interval:

Every 400 hours/Yearly (whichever

comes first)

1. Position the machine on a level surface.

2. Lower the boom and set the parking brake.

3. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

4. Allow the machine to cool completely.

5. Remove the top cover.

6. Remove the hydraulic tank filler cap and filter

7. Place a drain pan capable of hold 10 US Gallons

(37.8 l) under the hydraulic tank.

8. Pinch the hose clamp and slide the clamp and hose

off of the fitting on the hydraulic tank, allowing the

hydraulic fluid to drain from the hose and tank into

the pan.

Figure 58

1.

Hose

2.

Hydraulic tank fitting

3.

Hose clamp

9. When finished, install the hose onto the fitting and

secure it with the hose clamp.

Note:

Dispose of the used oil at a certified recycling

center.

10. Fill the hydraulic tank with approximately 6 US

gallons (23 l) of 10W-30 or 15W-40 detergent, diesel

engine oil (API service CH-4 or higher); refer to

Checking Hydraulic Fluid.

11. Add 8 fl oz (236 ml) of AMSOIL

®

Slip-Lock™

differential additive or an equivalent differential

additive to the hydraulic tank.

Note:

AMSOIL and Slip-Lock are trademarks of

AMSOIL Inc.

12. Install the hydraulic filter and filler cap (Figure 57)

and torque bolt on top to 110 to 140 in-lb (13 to

15.5 N-m).

13. Start the engine and let it run for a few minutes.

14. Stop the engine.

37