Checking and Greasing the Road

Wheels

Service Interval:

Every 250 hours

1. Remove the tracks; refer to Replacing the Tracks.

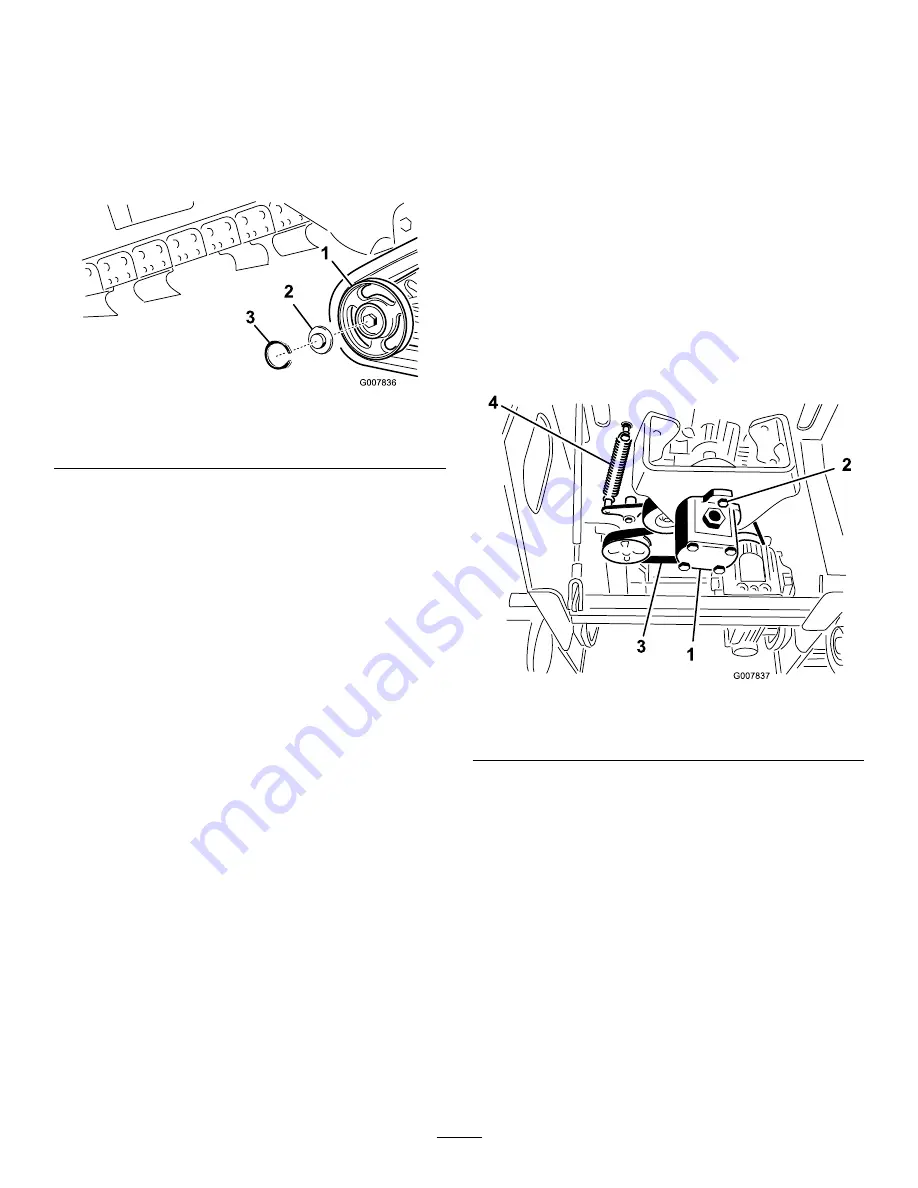

2. Remove the snap ring and cap from a road wheel

Figure 50

1.

Road wheel

3.

Snap ring

2.

Road wheel cap

3. Check the grease under the cap and around the

gasket (Figure 50). If it is dirty, gritty, or depleted,

clean out all of the grease, replace the gasket, and

add new grease.

4. Ensure that the road wheel turns smoothly on the

bearing. If it is frozen, contact your Authorized

Service Dealer to replace the road wheel.

5. Place the greased road wheel cap over the bolt head

6. Secure the road wheel cap with the snap ring

7. Repeat steps 2 through 6 for all 12 road wheels.

8. Install the tracks; refer to Replacing the Tracks.

Belt Maintenance

Replacing the Pump Drive Belt

If the pump drive belt begins to squeal or is cracked,

worn, or frayed, replace it. Contact you Authorized

Service Dealer for a replacement belt.

1. Raise the boom and set the parking brake.

2. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Raise the back of the machine and support it on jack

stands.

4. Remove the bottom shield; refer to Removing the

Bottom Shield.

5. Loosen the two pump bolts (Figure 51).

Figure 51

1.

Pump

3.

Belt

2.

Pump bolts

4.

Idler pulley spring

6. Twist the pump counter clockwise and allow it to

drop down away from the pulley (Figure 51). Ensure

that the spider coupler drops down with the pump.

7. Using a spring puller (contact your Authorized

Service Dealer) or stiff metal hook, pull the end of

the idler pulley sprint off of the spring bolt to release

tension on the belt (Figure 51).

8. Remove the belt.

9. Route a new belt around the pulleys.

10. Install the idler pulley spring on the bolt.

11. Ensure that the spider coupler is in place on the

pump and then insert it into the pulley, twisting it

clockwise to seat it on the pump bolts.

12. Torque the pump bolts to 50 ft-lb (68 N-m).

13. Install the bottom shield.

34