Installation

Valve Adjustment

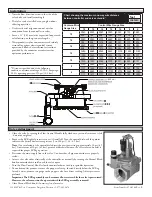

Chart showing the maximum one-way wire distance

between controller and valve solenoid *

feet

meters

Common Wire

Gauge Size

Control Wire Gauge Size

18

16

14

12

10

8

6

18

2040

2520

2940

3280

3540

3720

3860

622

768

896

1000

1079

1134

1177

16

2520

3260

4000

4660

5220

5620

5920

768

994

1219

1420

1591

1713

1804

14

2940

4000

5180

6360

7420

8300

8960

896

1219

1579

1939

2262

2530

2731

12

3280

4660

6360

8240

10100 11800 13180

1000

1420

1939

2512

3078

3597

4017

10

3540

5220

7420

10100 13180 16060 18770

1079

1591

2262

3078

4017

4895

5721

8

3720

5260

8300

11800 16060 20800 25540

1131

1603

2530

3597

4895

6340

7785

6

3860

5960

8960

13180 18700 25540 33080

1177

1817

2731

4017

5700

7785

10083

• Note the flow direction arrow in the side of the

valve body and install accordingly.

• The valve can be installed at any angle without

affecting operation.

• Use direct-burial irrigation control wire for

connection from the controller to valves.

• Leave a 12” (305 mm) wire expansion loop at each

valve location on long-run wire lengths.

• Waterproof wire splice connectors are absolutely

essential for proper electric control system

operation. Follow the installation instructions

provided by the connector manufacturer for

optimum performance.

*

Distances specified under the following

conditions: minimum voltage: 20 VAC, amperage:

0.12A, operating pressure: 150 psi (10,3 bar).

(if required)

(305 mm)

• Close the valve by turning the Flow Control Handle fully clockwise, just until resistance is felt

- do not overtighten!

• Remove the EZReg dial protective cover (if installed). Turn the control dial until the pointer

indicates the desired downstream pressure (5 to 100 psi) (,34 - 6,9 bar).

Note

: One revolution of the control dial adjusts the pressure setting approximately 10 psi (,69

bar). A minimum of 10 psi (,69 bar) pressure differential between the valve inlet and outlet is

required for proper EZReg operation.

• Pressurize the main supply line to the valve. Confirm that all pipe connections are properly

sealed.

• Actuate the valve either electrically at the controller, or manually by turning the Manual Bleed

knob counterclockwise solely until the valve opens.

• Turn the Flow Control Handle slowly counterclockwise to adjust sprinkler operation.

• To confirm outlet pressure, remove the poppet valve cap, located directly below the EZReg.

Attach a water-pressure test gauge to the poppet valve for a direct reading. Adjust pressure as

preferred.

Important: The EZReg assembly can be removed for service while the valve is pressurized.

However, the valve must not be operated with the EZReg assembly removed.

• Close Manual Bleed knob (if necessary) to close valve.

© 2016 The Toro Company • Irrigation Division • 1-877-345-8676

Form Number 373-0544 Rev. B