12

Installing the Transport Wheels

1. Push the kick stand down with your foot and pull up on

the handle to support the mower on the kick stand.

2. Apply #242 Loctite to the threads of the wheel shafts.

3. Thread the right hand wheel shaft into the drive pulley

on the right side of the machine (Fig. 4).

1

Figure 4

1.

Right hand wheel shaft

4. Torque the shaft to 65 to 75 ft-lb. (88 to 101 N

⋅

m)

Note: The right hand wheel shaft has left hand threads.

5. Apply Never–Seez to the exposed ends of the axles and

slide the wheel onto the axle (Fig. 5).

6. Pivot the wheel locking clip away from center of the

wheel allowing it to slide farther onto the axle (Fig. 5).

7. Rotate the wheel back and forth until it slides

completely onto the axle and the locking clip is secured

in the groove on the axle shaft.

1

Figure 5

1.

Locking clip

8. Repeat the procedure on the opposite side of the

machine.

9. Inflate the tires to 12 to 15 psi. (574 to 718 Pa).

Before Operating

Adding Engine Oil

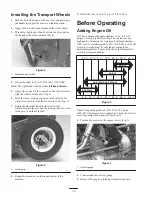

Fill the crankcase with approximately 20 oz. (0.6 l) of

proper viscosity oil before staring. The engine uses any

high-quality oil having the American Petroleum Institute —

APl—service classification SC, SD, SE, SF, SG, or SH. Oil

viscosity (weight) must be selected according to the

ambient temperature. Figure 6 illustrates the temperature/

viscosity recommendations.

SAE 5W20

–4

F

14

F

32

F

50

F

68

F

86

F

104

F

SAE 10W30/ SAE 10W–40

SAE 30

SAE 40

–20

C –10

C 0

C

10

C

20

C

30

C

40

C

Figure 6

Note: Using multi grade oils (5W–20, 10W–30 and

10W–40) will increase oil consumption. Check the oil level

more frequently when using multi grade oils.

1. Position the mower so the engine is level (Fig. 7).

1

Figure 7

1.

Oil level gauge

2. Clean around the oil level gauge.

3. Remove the gauge by rotating it counterclockwise.