Tormach, Inc.

P: 608.849.8381 / F: 209.885.4534

tormach.com

TECHNICAL DOCUMENT

Page 7

©Tormach® 2020. All rights reserved.

Specifications subject to change without notice.

TD10487_PCNC440_ATC_Install_1220A

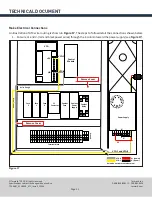

6. From the ATC’s motor enclosure, on the access

plate, use a Phillips screwdriver to remove

four M4 x 6 mm screws (see

Figure 8

).

Set aside the screws and the access plate.

7.

On the ATC’s wires, use a snips to cut the cable

ties.

CAUTION! Heavy Object:

Use two people to

lift and install the ATC on the mill’s Z-column. Failure

to do so could result in serious injury and/or machine

damage.

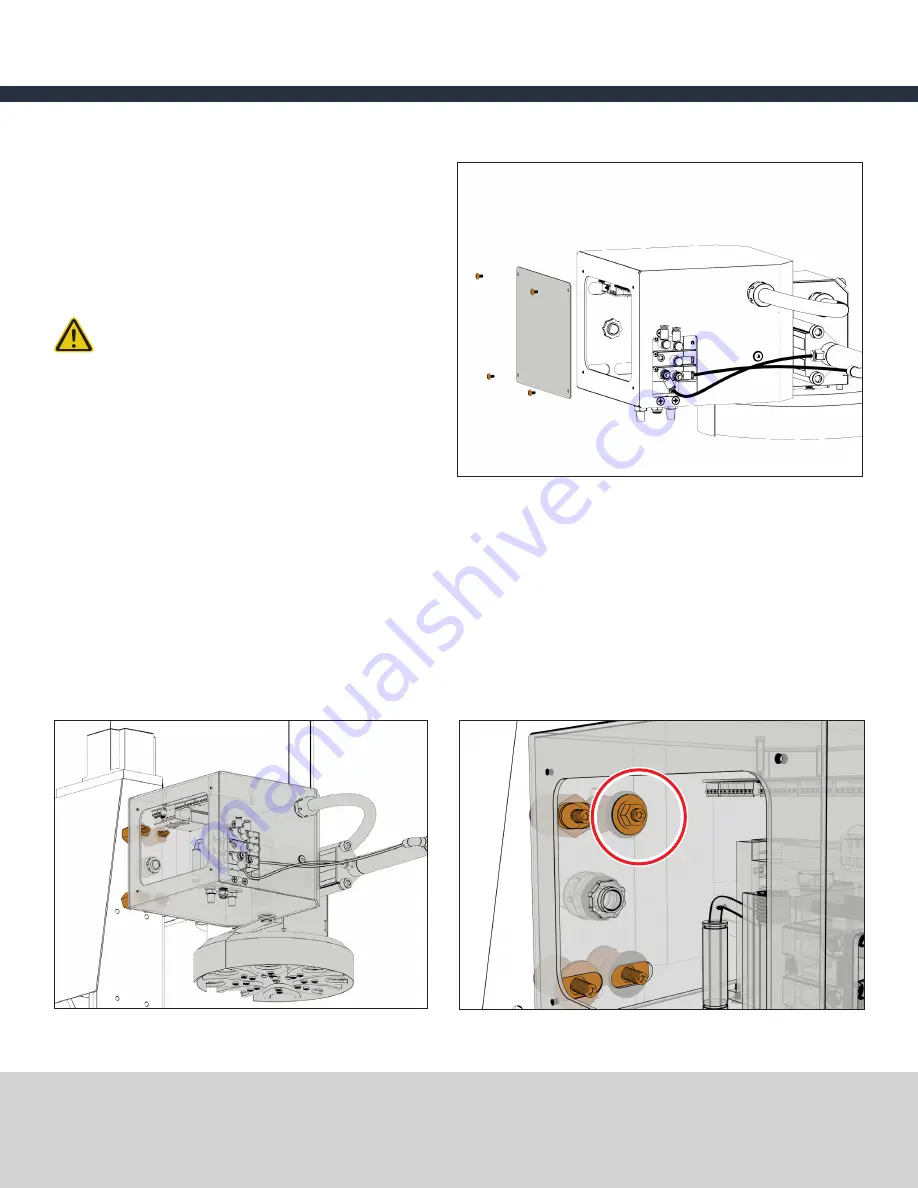

8.

On the mill’s Z-column, hold the oil line above

the four standoffs and put all ATC wires

through the Z-column’s access slot.

Continue to hold the oil line above the four standoffs.

9. Temporarily rest the ATC on the standoffs (see

Figure 9

) and release the oil line.

The oil line is clear of interference.

10.

On the top right standoff, re-install the washer and flange nut removed in Step 5 (see

Figure 10

).

NOTE:

Tighten the washers and flange nuts finger-tight. Adjustments are made later in this document.

11.

On the remaining three standoffs, re-install the washers and flange nuts set aside in Step 5.

Figure 9

Figure 10

Figure 8