5

Step 2

•

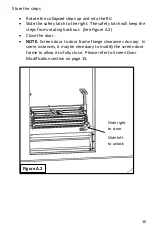

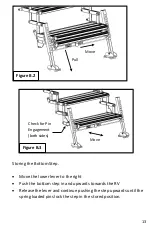

Remove the GlowStep Revolution Uprising (GSRU) from the

packaging.

•

Extend the steps to their fully open position. Move the lower step

latch lever to the right to unlock the lower step. (See figure 2.1)

•

Rest the main bracket inside the door frame. If required, adjust the

All-Terrain Landing Gear to allow the main bracket to sit against the

floor inside of the threshold molding.

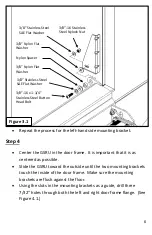

Step 3

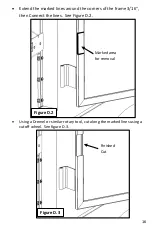

•

Install the right-hand side mounting bracket to the main bracket as

shown in Figure 3.1. Leave the hardware loose enough to slide in

the slotted hole in the mounting bracket.

Figure 2.1

Move lever

to the right

Expand

Steps

All Terrain Landing Gear Adjustment

Main

Bracket