32

Grade Setting Error

Perform the following check only after completing "Horizontal Calibration" and “Hori-

zontal Rotation Cone Error” procedures.

(1) Checking

1

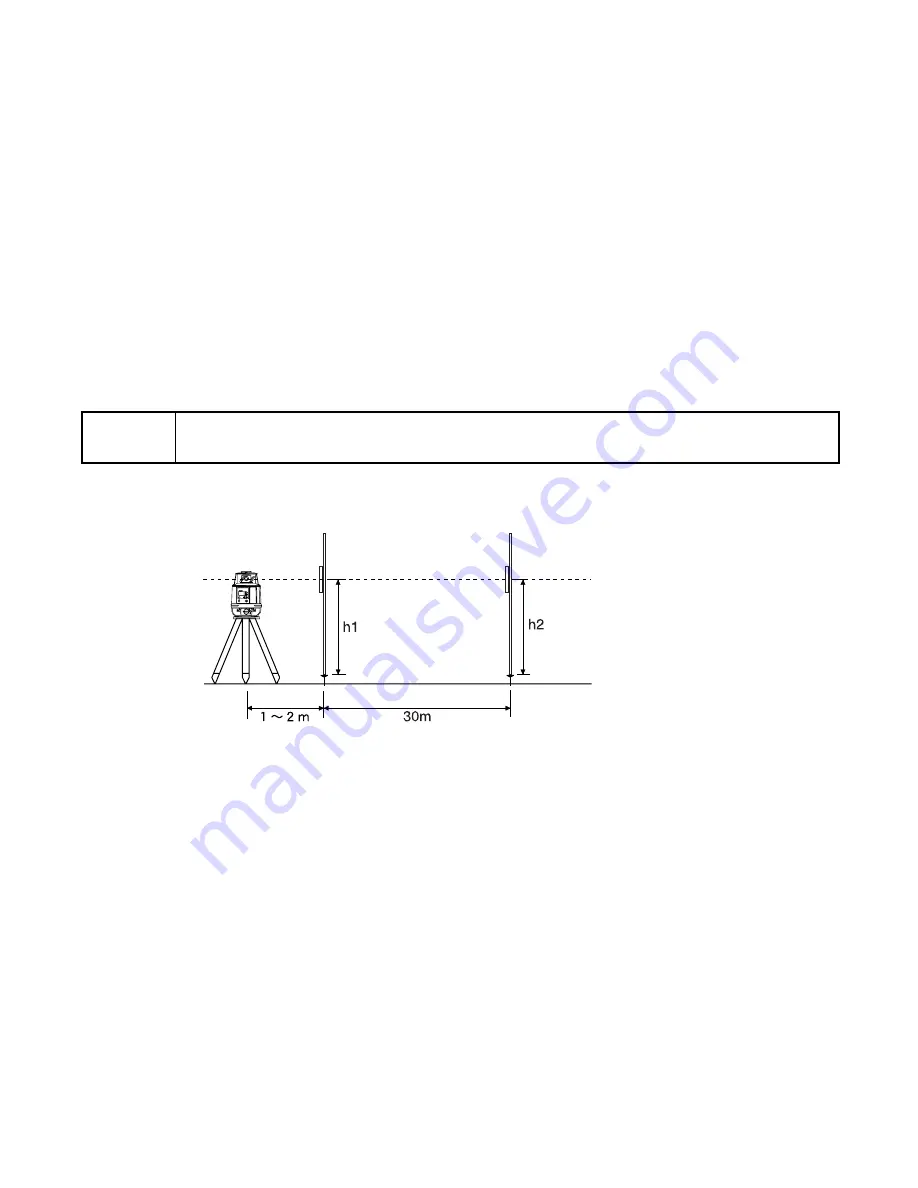

Securely position two nails or stakes exactly 30m (93 ft) apart. These positions will be

called Nail 1 and Nail 2.

2

Set up the instrument on a tripod approximately 1m to 2m (3 ft to 6 ft) in front of Nail 1 on

the line created by Nail 1 and Nail 2. Position the instrument so the X-axis is exactly

aligned to the line created by Nail 1 and Nail 2.

3

Turn on the instrument and verify the grade setting is 00.000%. Turn on the LS-70 laser

sensor and set it to high precision detection. Using the rod, read the elevation of the laser

Note

• Due to the accuracy required to perform this check, the rod used in this pro-

cedure must be graduated in millimeters.

X

rpm

100

MANU

×

POWER

%

ON

ENT

Nail 1

Nail 2

Laser Sensor

Rod

Rod

Summary of Contents for RL-H2Sa

Page 1: ...INSTRUCTION MANUAL ROTATING LASER RL H2Sa POWER MANU ON ENT X Y RL H2Sa x100 rpm...

Page 2: ......

Page 47: ......