Calibration

Boom Sensor

47

Excavator Indicate System

P/N: 1022461-01

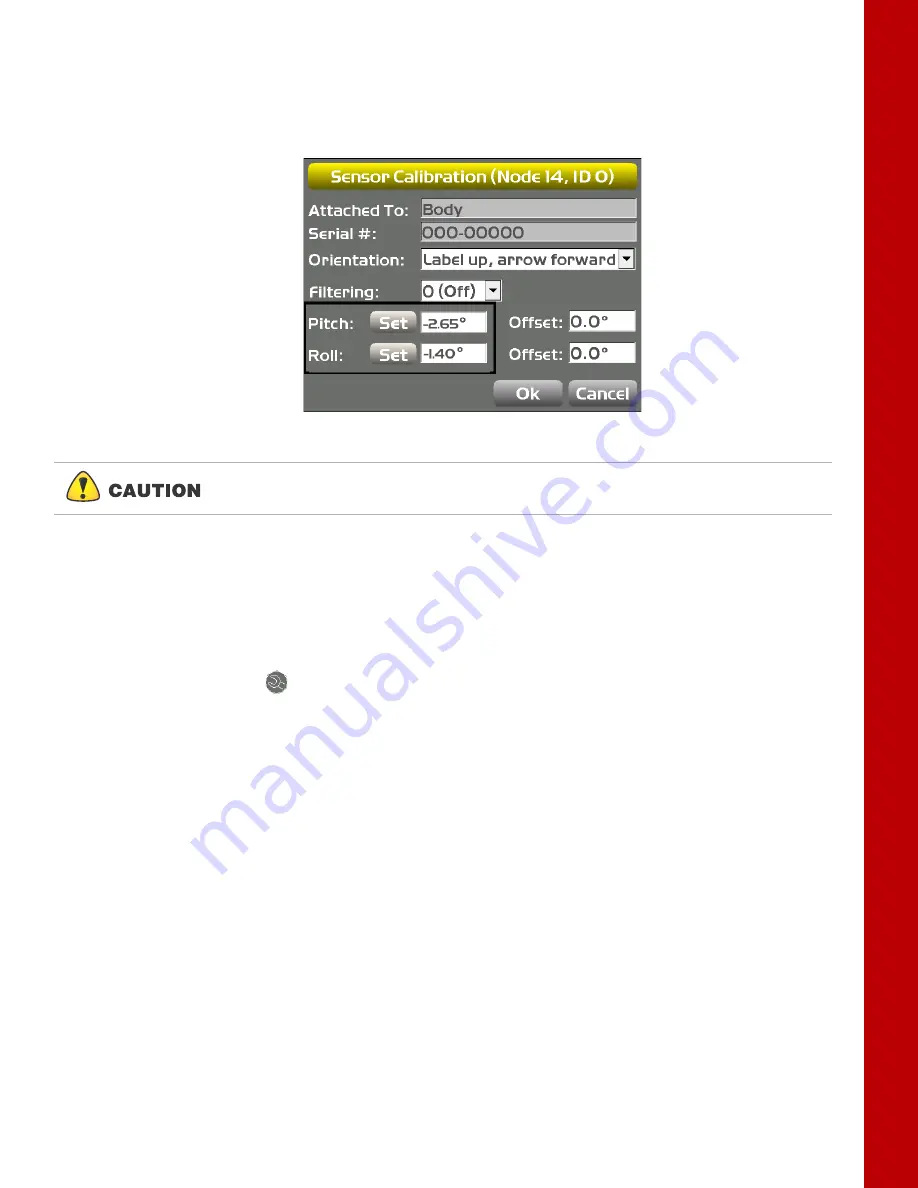

10. Without moving the tracks, rotate the machine 180° (Position 2) as shown in Figure 60 on

page 46.

11. Tap

Set

next to

Pitch

, set the value to

half the displayed values, and tap

Set

again

(i.e. -5.3/ 2 = -2.65 and -2.8/ 2 = -1.4) (Figure 62); repeat for the

Roll

value, and then tap

OK.

Figure 62: Set Pitch and Roll Value to Half of Displayed Values

12. Tap

Ok

to return to the

Excavator Frame/Sensor

screen.

Boom

S

ensor

When performing the boom sensor calibration, a laser is recommended to correctly position the boom

at zero degrees

.

1. Tap the

Wrench

icon that corresponds to the boom sensor (Figure 64).

2.

Select the correct orientation from the drop-down menu.

3. Ensure the machine is parked on a flat and stable surface, and that the Body Sensor reads a 0.0

degree roll.

4. Place a zero slope rotating laser along the side of the machine to shine on both the boom pivot

and stick pivot.

5. Adjust the laser height to strike the center of the boom pivot (Figure 63).

6. Move the boom to align the stick pivot with the laser (Figure 63).

Once the body sensor roll value is calibrated, rotate the machine until the body

Roll is 0.0. The remaining sensors require 0.0 Roll to be calibrated.