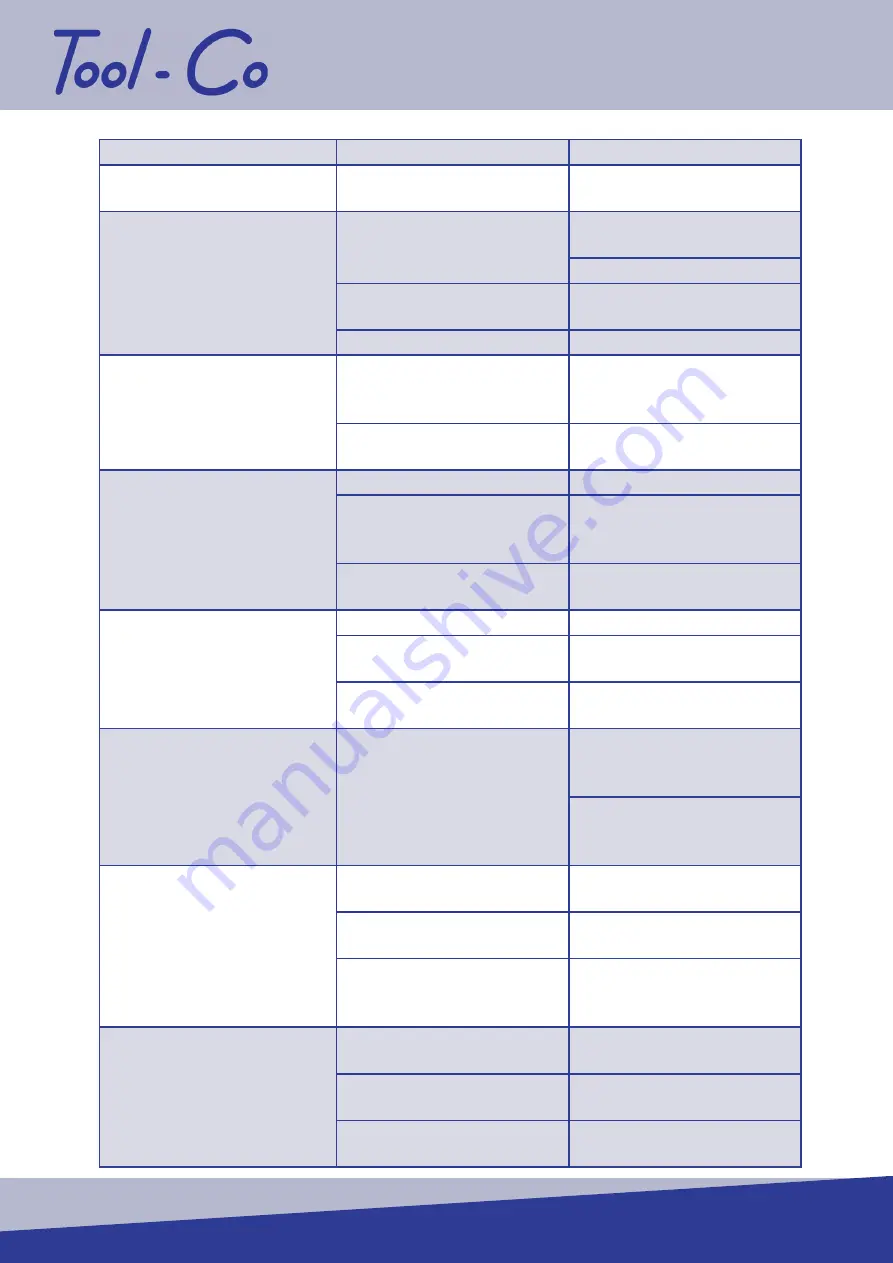

BCA350

Symptom

Possible Cause

Action

Irregular run of the saw

blade

Poor tension in the blade

material

Return the saw blade to the

manufacturer

Saw blade wobbles when

the saw is running

Saw blade is damaged or

bent

Have the saw blade

aligned or fl attened

Clean the receiving fl ange

Flange of the saw blade is

damaged

Replace the saw blade

fl ange

Shaft of the motor is bent

Replace the electric motor

Diamond segment becomes

loose

Overheating of the saw

blade

Have the diamond segment

soldered on the blade

again

Coolant is not suffi cient

Ensure optimum fl ow of

cooling water

Excessive wear

Wrong type of saw blade

Use a harder blade bond

Shaft of motor causes

wobbling

Have bearings of the motor

replaced, or replace the

motor

Overheating

Ensure optimum fl ow of

cooling water

Cracks in or near the

diamond segment

Saw blade bond too hard

Use a softer blade bond

Fixed fl ange is worn out

Have the fi xed fl ange

replaced

Motor shaft bearing is worn Replace the bearing of the

motor shaft

The center hole in the saw

blade has become wider

due to wear

The saw blade has slipped

on the motor shaft when

running

The arbor of the saw blade

must be fi tted with an

adapter ring

Check the receiving fl ange

and have it replaced if

necessary

Appearance of cut is not

optimal

Poor tension in the blade

material

Return the blade to the

manufacturer

Too much load placed on

the saw blade

Use a suitable blade

Diamond segments are

blunt

Sharpen the diamond

blade on an abrasive

material

Grinding marks on the saw

blade

Material is not being fed

parallel to the saw blade

Ensure that the direction of

feed is parallel to the blade

Poor tension in the blade

material

Adjust the roller table or

have it adjusted

Too much load on the

blade

Exert less pressure when

cutting, proceed slower

Pg.7

Summary of Contents for BCA350

Page 1: ...OPERATING MANUAL BCA350 MASONRY SAW...

Page 2: ......

Page 12: ...BCA350 Pg 9 Pg 10 EXPLODED DIAGRAM A...

Page 16: ...BCA350 EXPLODED DIAGRAM B Pg 13...

Page 20: ...BCA350 Pg 17...