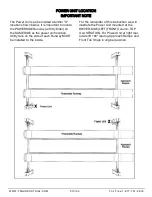

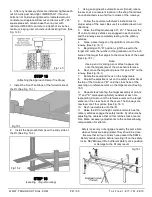

Fig 14.4

NOTE:

There will be initial stretching of the cables in the

beginning and/or with increased loads. Adjust the

Cables as outlined above a week after first use, then

every three to six months thereafter depending on

usage and/or to compensate for stretch.

8. Press the safety lock release handle and HOLD, and

check that all Safety Locks are functioning

properly.Lower the lift by pressing the power unit

lowering valve simultaneously.

KEEP HANDS AND FEET CLEAR. Remove hands and

feet from any moving parts. Keep feet clear of lift when

lowering. Avoid pinch points

9. Check all MAIN SAFETY LOCKS to make sure

they move freely and spring back to the lock position

when released. Lubricate all SAFETY PIVOT points

with

WD-40 or equal.

10. Run the lift up and down a few times to

ensure that the Locks are engaging uniformly and

that the safety release mechanisms are

functioning. Re-adjust if necessary

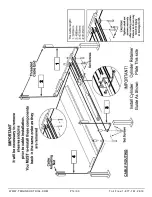

STEP 14

(Anchoring The Columns)

IMPORTANT NOTE:

The lifts are supplied with installation instructions

and concrete fasteners meeting the criteria as

prescribed by the American National Standard

"Automotive Lifts - Safety Requirements for

Construction, Testing, and Validation" ANSI/ALI

ALCTV-2011. Lift buyers are responsible for any

special regional structural and/or seismic anchoring

requirements specified by any other agencies and/or

codes such as the Uniform Building Code (UBC)

and/or International Building Code (IBC).

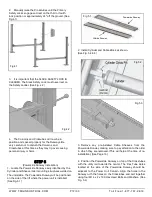

1.

Before proceeding, double check the

measurements and make certain that the bases of

each Column are square and aligned with the chalk

line. Raise the lift up and down and make sure it

operates properly at the locations prescribed by the

markings on the floor.

(See Fig. 14.1)

Fig. 14.1

2.

Using the Base plate on each Column as a guide,

drill each anchor hole approximately 4-1/2” deep using

a rotary hammer drill and 3/4” concrete bit.

(See Fig. 14.2)

Fig. 14.2

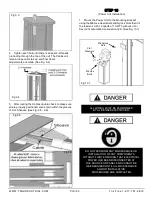

3.

After drilling, remove dust thoroughly from each

hole using compressed air and/or bristle brush. Make

certain that the Columns remain aligned with the chalk

line.

ALWAYS WEAR SAFETY GOGGLES

4.

Assemble the Washers and Nuts on the anchors

then tap each hole with a hammer until the washer rests

against base plate. Be sure that if shimming is required,

enough threads are left exposed. (See Fig. 14.3)

5.

If shimming is required, insert the shims as necessary

the base plate so that when the anchor bolts are tight-

ened, the columns will be plumb. (See Fig. 14.4)

Fig 14.3

WWW.TMGINDUSTRIAL.COM

P20/33

Toll Free:1-877-761-2819

Noted: the shims

not include