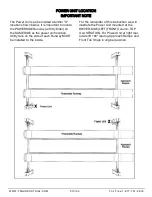

STEP 8

(Cable / Sheave Installation)

1.

Inspect Cables to ensure proper lengths. All

Cables should have ID tags showing proper Cable

lengths.

2.

In order to install the Cables it is necessary to first

extend the Hydraulic Cylinder. Remove both Cylinder

port plugs then use an air gun or come-along to extend

the Cylinder.

IMPORTANT! - Be careful not to damage the chrome rod

during this step. (See Fig. 8.1)

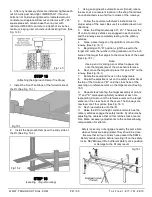

Fig 8.1

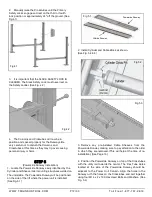

3.

You must re-install the Sheaves and Pins in the

same order as they are removed. (See Fig. 8.2)

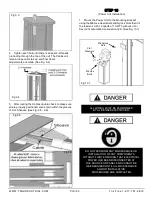

DO NOT PROCEED unless visual confirmation

is made of ALL Safety Locks. ALL locks MUST

be engaged before proceeding. Failure to

comply with these instructions may result in

severe personal injury or death. (See page 11.)

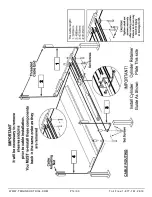

STEP 9

(Cable Installation)

1.

The Cylinder Flange Plate MUST be installed with the

Guide Assembly facing down, the welded on Spacer

towards the Cylinder and the Cylinder Retainer plate on

the outside of the guide. Lug ends of Cables start at

Cylinder. (See Fig. 9.1)

2.

Route the threaded Cable ends through the ends

of each Crosstube. Care must be taken when routing

the Lifting Cables to ensure they are routed below the

Crosstube Mounting Bolts. (See Fig 9.2)

Fig 9.2

3.

Route Cables over the Slack Safety Sheaves then to

the top of each Column. Secure using the M20 Hex

Head Nuts and Flat Washers. (See Fig. 8.3)

Fig 9.1

Fig 8.2

Failure to route Lifting Cables as described may lead to

serious personal injury and/or death to operator or

bystander and/or may cause damage to property.

WWW.TMGINDUSTRIAL.COM

P15/33

Toll Free:1-877-761-2819