172-65702M-04 (SQ-C01) 10 Dec 2020

18

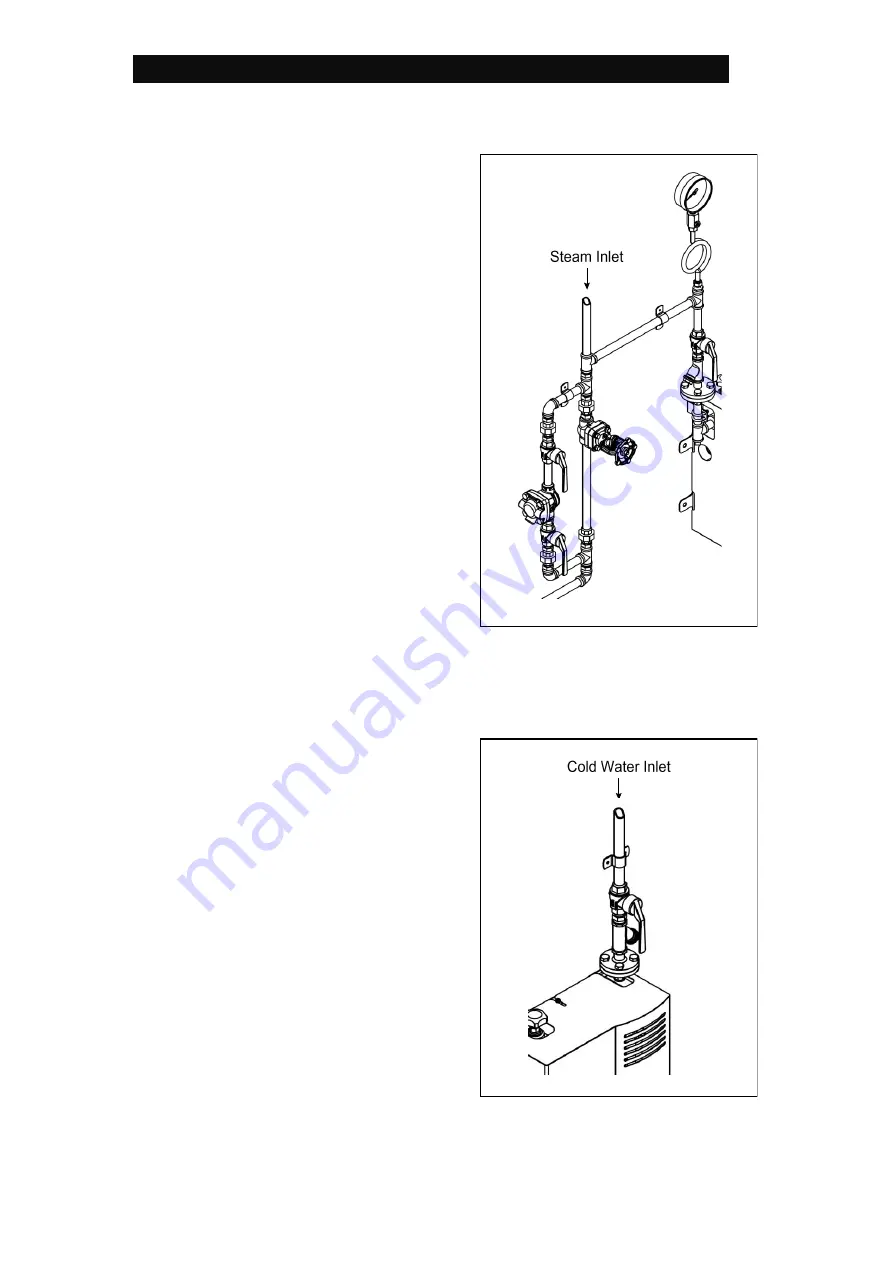

(1) Steam Inlet Piping

a) Install a pressure gauge at the

steam inlet.

Supply steam pressure range:

0.2 to 0.7 MPaG.

b) Make sure to install piping

support(s) for the steam inlet

piping.

c) Install a valve for emergency shutoff

and maintenance at the steam

inlet.

d) Make sure to install a strainer at

steam inlet.

e) Install a steam trap upstream of the

unit to prevent condensate in the

steam transportation line from

flowing into the unit.

f) When recovering the condensate,

install a check valve on the

secondary side of the steam trap to

prevent backflow.

g) Make sure to insulate the steam

piping as it becomes very hot.

h) When using a pressure reducing

valve to supply steam to the unit, make sure to install a safety valve on the

secondary side of the pressure reducing valve if the pressure on the

primary side of the pressure reducing valve exceeds 0.7 MPaG.

(2) Cold Water Inlet Piping

a) Make sure to install piping

support(s) for the cold water inlet

piping.

b) Install a valve at the cold water inlet

for maintenance. (The valve is

included with the optional

valve/strainer set for the JIS

specification model.)

c) Install a strainer at the cold water

inlet to prevent malfunction of

internal safety functions.