172-65207MA-08 (SR-3/SR-8) 8 Oct 2020

19

Inspection and Maintenance

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

As the SR is an atmospheric type heat exchanger, there is no particular need to

perform the kind of maintenance inspections required for pressure vessels.

However, if the heat exchanging performance declines, verify that the cold water and

steam flow quantity are in compliance with the rated capacities. If they are not in

compliance, correct the flow quantities. If there are no irregularities with the flow

quantities, perform the following inspection:

Annual inspection and cleaning is recommended to prolong the product

’s service life.

Inspection at cold/hot water side

1. Perform a reverse-flow chemical cleaning by pouring cleaning solution in through

the hot water outlet valve on the SR, then discharging the solution through the

cold water inlet valve.

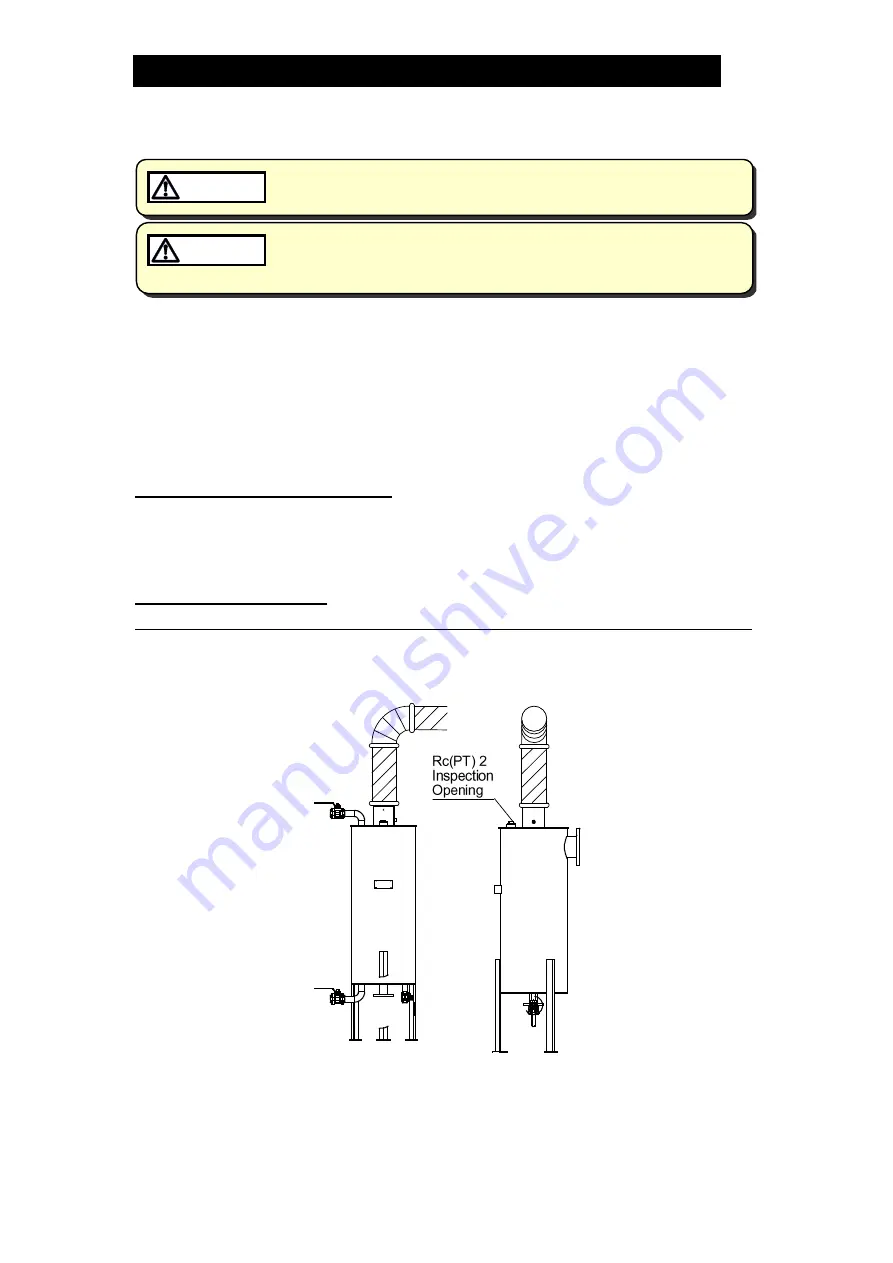

Inspection at steam side

1. Remove the plug from the inspection opening and check the condition inside the tank.

2. If the inspection reveals heavy grime, close the condensate outlet and the

condensate blowdown outlet and perform chemical cleaning by pouring cleaning

solution through the exhaust outlet of the SR.