13

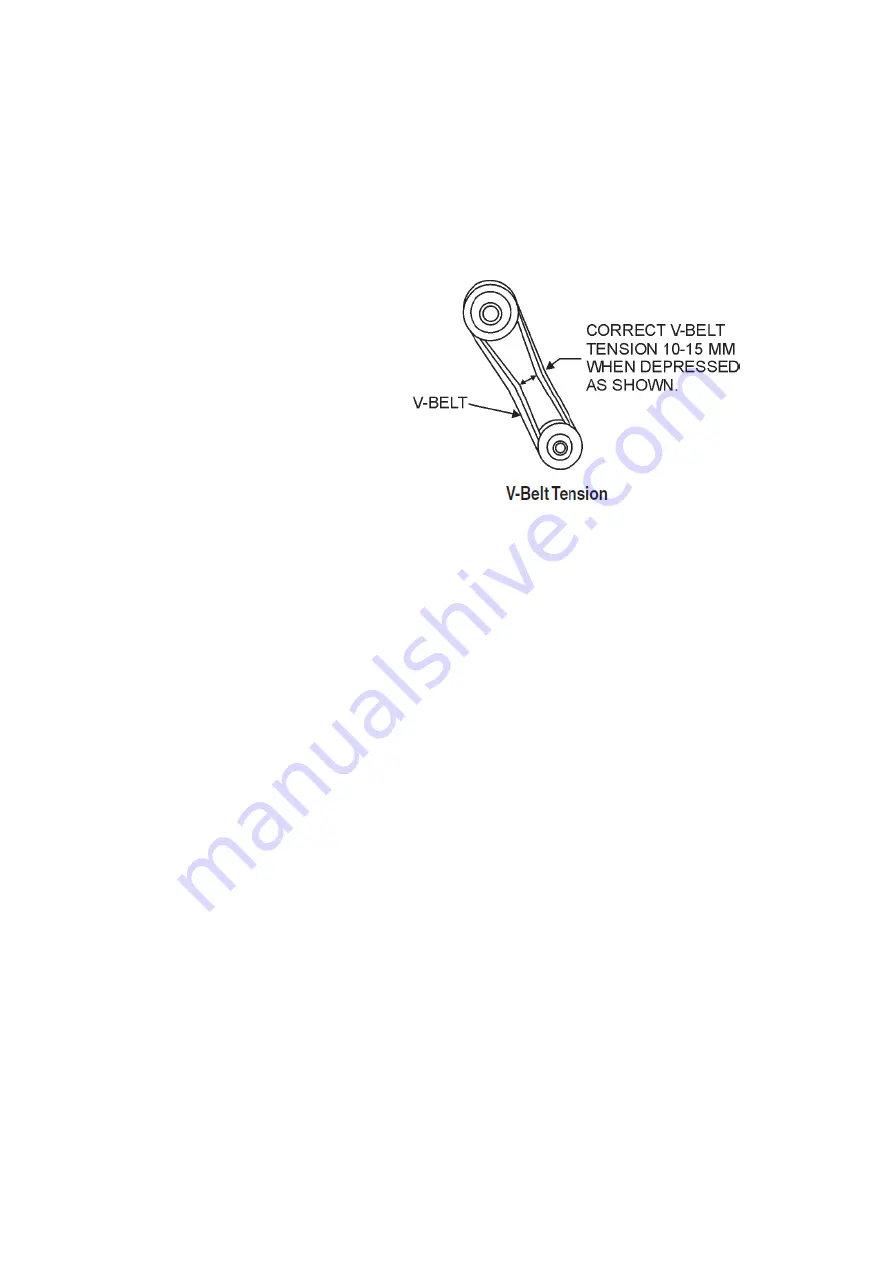

BELT TENSION

1.

If there is excessive belt play, there will be a decrease in the grinding action,

which could cause cage and machine damage. The normal belt play should be

3/8” to 1/2” which is attained by depressing the top section of the belt at the

belt guard mounting bracket location. When adjusting the belt make sure that

the drive pulley is in alignment with cage pulley. Tighten all engine mount bolts,

adjust the two engine-stop bolts, and tighten lock nuts.

REPLACING V-BELT/CLUTCH

1.

Remove the belt cover.

2.

Place an offset wrench (13 mm) or the like on the vibrator pulley (lower)

Fastening bolt.

3.

Using a waste cloth or the like, pull the V-belt back strongly at midway of the

belt on the left side and rotate the offset wrench clockwise so that the V-belt

will come off.

4.

Check the clutch and replace as necessary, following the procedures listed in

Checking the Clutch.

5.

Place the V-belt on the lower vibrator pulley. Push the V-belt to the left side of

the upper clutch and rotate the offset wrench clockwise so that the V-belt

moves onto the pulley.

REPLACING CLUTCH

6.

With belt cover removed, visually check outer drum of the clutch for seizure

and "V" groove for wear or damage.

7.

Clean the "V" groove as necessary.

8.

Check the clutch lining and shoe for signs of wear. If the shoe is worn, replace

the clutch to prevent deficient power transmission and slippage.

9.

If Clutch must be replaced, first remove V-belt.

10.

Remove bolt at engine power output by tapping an engaged wrench (e.g.

tapping with hammer) and rotate the bolt counterclockwise.

11.

Remove clutch with a pulley extractor.

12.

To install a new clutch, reverse steps 1-3.

Discount-Equipment.com