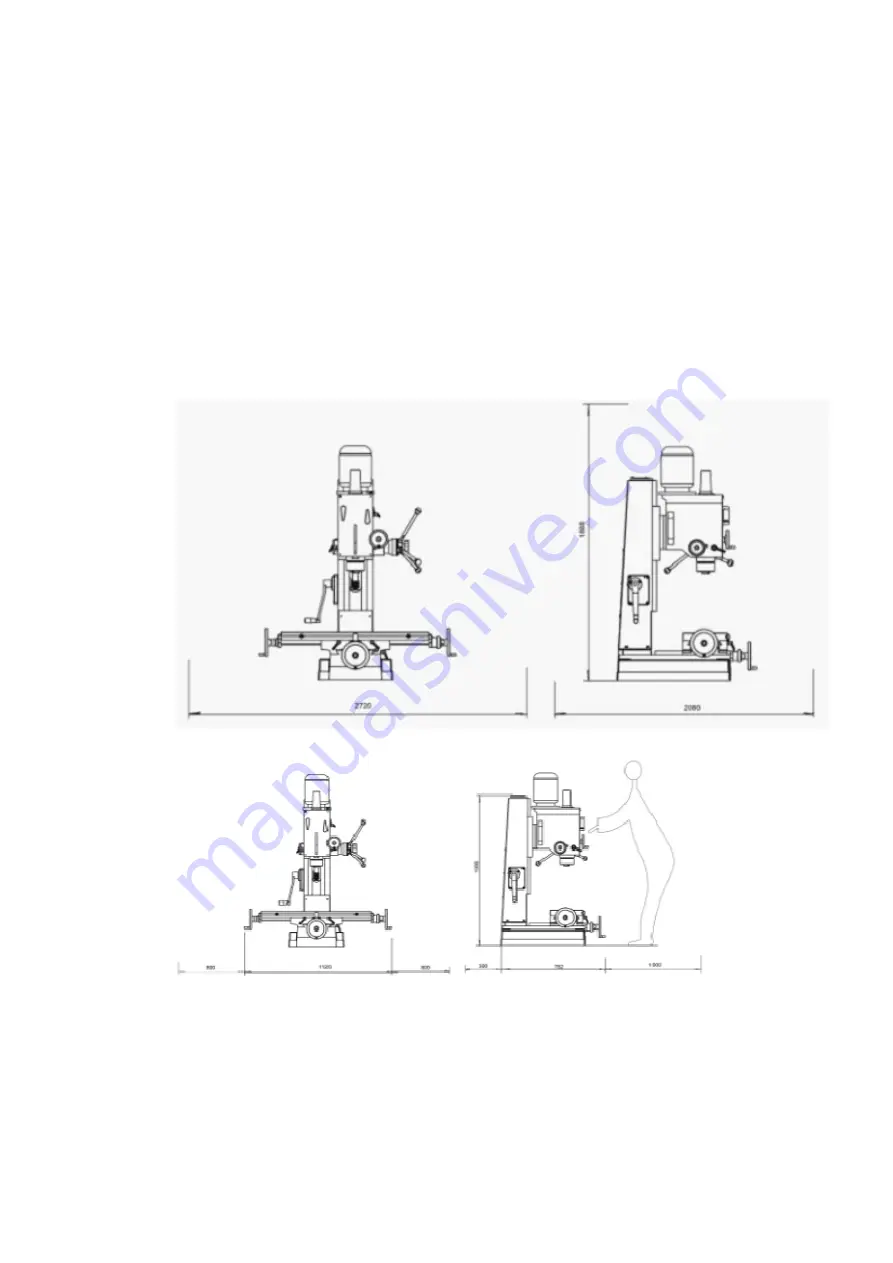

The smallest site area of this machine is the circle area which

table moves one circle around the column. Please consider the

work piece, tool box, accessories area, operation space,

maintaenance space (as Dia. 4) when machine taking its’ place.

Too close to the wall , other machines or objects is un-easy and

un-safe.。

Dia. 4

Machine far away from the sunshine and keep the

environment dry and clean.