© Titan Tool Inc. All rights reserved.

25

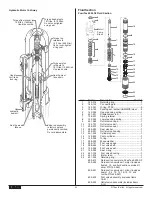

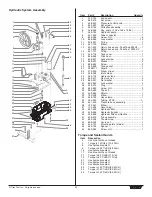

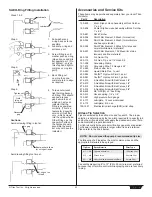

Servicing the PowrTex 6900 SF Fluid Section

IMPORTaNT: use of non-Titan service parts may void

warranty. ask for original parts made by Titan for best

services. This pump should receive a routine servicing

after approximately 1,000 hours of use. Earlier servicing is

required if there is excessive leakage from the top packing

or if pump strokes become faster on one stroke or the other.

The use of Titan Piston Lube (P/N 314-480) is recommended

as an upper packing lubricant. Do not substitute oil, water, or

solvent for an upper packing lubricant.

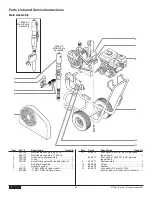

Disassembling the Fluid Section

1. Remove the foot valve housing (22), pump cylinder (15),

and cylinder spacer (14) with a strap wrench.

2. Slide the retaining ring (1) up with a small screwdriver,

then push the connecting pin (2) out.

3. Pull the displacement rod (6) through the lower cavity of

the motor/pump block.

4. Remove the

PTFE

o-ring (3), upper packing spring (5),

and upper packing set (4) from the motor/pump block.

5. Hold the displacement rod (6) in a vise by the flats at the

top of the displacement rod. Remove the outlet valve

housing (13) with a wrench while holding the displacement

rod horizontal with a wooden support, if necessary.

Remove the seal washer (12), outlet valve seat (11), outlet

valve ball (10), outlet valve cage (9), lower packing set (4),

lower packing spring (8), and spring retainer (7).

6. Using a 1/2” extension bar attached to a 1/2” drive ratchet,

insert the end of the extension bar into the square opening

of the foot valve cage (18) inside the foot valve housing

(22). Unscrew and remove the foot valve cage along with

the wave washer (17) from the foot valve housing.

7. Remove the

PTFE

o-ring (3), foot valve ball (19), foot

valve seat (20), and seat o-ring (21) from the foot valve

housing (22).

8. Remove the o-ring (16) from the pump cylinder (15).

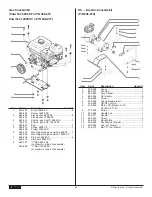

Reassembling the Fluid Section

NOTE: Use

PTFE

tape on all threaded pipe connections.

1. Place a new seat o-ring (21) into the groove in the bottom

of the foot valve housing (22).

2. Inspect the foot valve seat (20) for wear. If one side is

worn, flip the seat to the unused side. If both sides are

worn, install a new seat. Place the new or flipped seat

(worn side down) into the bore at the bottom of the foot

valve housing (22).

3. Place a new foot valve ball (19) onto the foot valve seat

(20). Using a 1/2” extension bar attached to a 1/2” drive

ratchet, insert the end of the extension bar into the square

opening of the foot valve cage (18) and screw the cage

into the foot valve housing (22). Torque the cage to 300

in./lbs. (25 ft./lbs.).

4. Place the wave washer (17) on top of the foot valve cage

(18).

5. Insert a new

PTFE

o-ring (3) into the groove of the foot

valve housing (22). Lubricate the o-ring using oil or grease.

6. After soaking the new leather packings in oil (preferably

linseed oil), reassemble the lower packing set (4). Place

the set onto the outlet valve housing (13) with the peak

of the “V” packings pointing down toward the hex on the

outlet valve housing.

7. Inspect the outlet valve seat (11) for wear. If one side is

worn, flip the seat to the unused side. If both sides are

worn, use a new seat. Insert the outlet valve cage (9),

new outlet valve ball (10), new or flipped seat (worn side

away from ball), and a new seal washer (12) into the

displacement rod (6).

8. Clean the threads on the outlet valve housing (13) and

coat the threads with blue Loctite #242. Make sure the

Loctite is only on the threads.

9. Place the lower packing spring (8) onto the outlet valve

housing (13) followed by the spring retainer (7).

10. Screw the displacement rod (6) and the outlet valve

housing (13) together. Tighten in a vise to 900 in./lbs. (75

ft./lbs.).

11. Insert the

PTFE

o-ring (3) into the upper grove of the

motor/pump block.

12. Insert the upper packing set (4) into the motor/pump block

with the peak of the “V” packings pointing up toward the

motor.

NOTE: The packings must be soaked in oil before

installation.

13. Place the upper packing spring (5) into the motor/pump

block with the small tapered end facing up toward the

motor/pump block.

14. Insert the displacement rod (6) up through the upper

packings in the motor/pump block.

15. Align the holes in the displacement rod (6) and the

hydraulic piston rod and insert the connecting pin (2).

Replace the retaining ring (1) over the connecting pin.

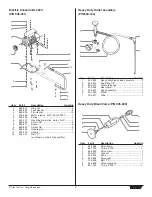

16. Thread the short threads of cylinder spacer (14) into the

motor/pump block and tighten with a strap wrench.

17. Thread the short threads of the pump cylinder (15) into the

cylinder spacer (14) and tighten with a strap wrench.

18. Place the o-ring (16) onto the top grove of the pump

cylinder (15).

19. Thread the foot valve housing (22) onto the pump cylinder

(15), tighten with a strap wrench.

NOTE: It is not necessary to over-tighten the foot valve.

O-ring seals perform sealing function without

excessive tightening. Full thread engagement

is sufficient. The foot valve may be rotated

backward up to 1/2 turn from full engagement for

convenient hose position.

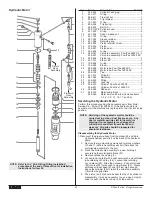

Fluid Section cut-away

Peaks of upper

packings must

face up.

Torque outlet

valve housing

to 75 ft./lbs.

(1095 N/m).

Use blue

Loctite.

Oil cup area

for piston lube

packing

lubricant.

Peaks of lower

packings must

face down.

Lubricate O-ring.