© Titan Tool Inc. All rights reserved.

11

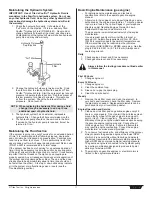

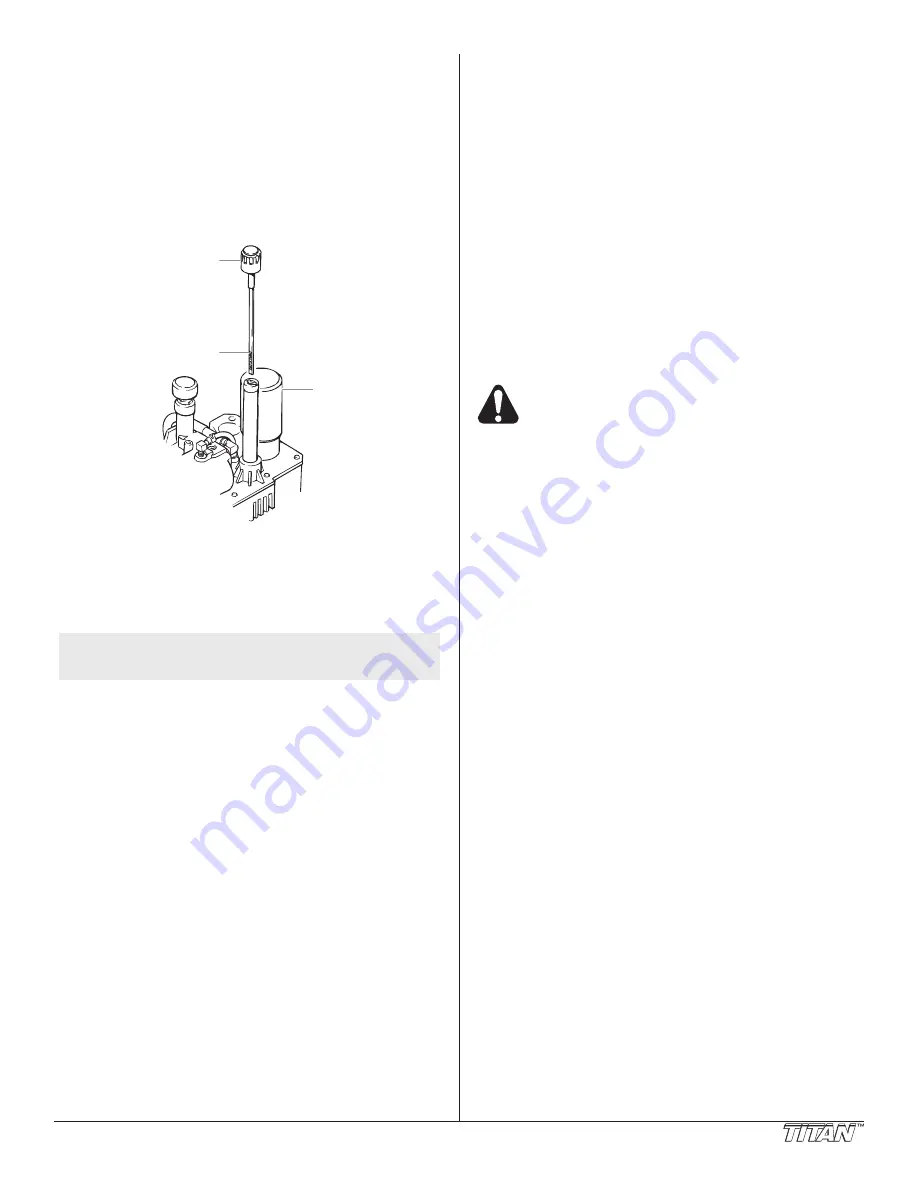

Maintaining the hydraulic System

IMPORTaNT: use of Titan’s coolflo™ hydraulic Fluid is

mandatory in the PowrTwin hydraulic system. Do not use

any other hydraulic fluid. use of any other hydraulic fluid

may seriously damage the hydraulic system and will void

the warranty.

1. Check the hydraulic fluid daily. It should be at the

“Full” mark on the dipstick. If it is low, add only Titan

Coolflo™ Hydraulic Fluid (P/N 430-361). Never add or

change hydraulic fluid except in a clean, dust-free area.

Contamination of the hydraulic fluid will shorten hydraulic

pump life and may void warranty.

"Full" Mark

Hydraulic Fluid

Cap/Dipstick

Hydraulic

Filter

2. Change the hydraulic fluid every twelve months. Drain

the old fluid from the tank and fill with 4 quarts of Titan

Coolflo™ Hydraulic Fluid. Start the sprayer at just enough

pressure to operate the fluid section. Run the sprayer at

this low pressure for at least 5 minutes. This removes

air from the system. Check the fluid level after this

procedure. Do not over-fill.

NOTE: When replacing the hydraulic filter during a fluid

change, it may be necessary to add up to one

additional quart of hydraulic fluid.

3. The hydraulic system has an external, replaceable

hydraulic filter. Change the filter every twelve months.

4. The hydraulic pump should not be serviced in the field.

If service on the hydraulic pump is required, it must be

returned to Titan.

Maintaining the Fluid Section

If the sprayer is going to be out of service for an extended period

of time, it is recommended that following cleanup, a kerosene

and oil mixture be introduced as a preservative. Packings may

tend to dry out from lack of use. This is particularly true of the

upper packing set for which upper packing lubricant Piston Lube

(P/N 314-480) is recommended in normal usage.

If the sprayer has been out of service for an extended period of

time, it may be necessary to prime the suction by pouring some

of the paint solvent into the siphon tube to restart. It is extremely

important that the threads on the siphon hose coupling are

properly sealed. Any air leakage will produce erratic operation of

the sprayer and may damage the system. The up and the down

strokes should be approximately equal in time (one should not

be faster than the other). A fast up or down stroke may indicate

air in the system or malfunctioning valve or seats (see the

Troubleshooting section).

Basic Engine Maintenance (gas engine)

• For detailed engine maintenance and technical

specifications refer to the separate gasoline engine

manual.

• All service to the engine should be performed by a dealer

authorized by the engine manufacturer. To locate a dealer

in your area, look in the Yellow Pages of your telephone

directory under Gasoline Engines, Garden & Lawn

Equipment & Supplies, Lawn Mowers, etc.

• The gas engine is warranted exclusively by the engine

manufacturer.

• Use a premium quality motor oil certified to meet or

exceed U.S. Automotive requirement SG.or SF. SAE

10W30 is recommended for general all temperature use.

Other viscosities may be required in other climates.

• Use only a (NGK) BP6ES or BPR6E spark plug. Gap the

plug to 0.028 to 0.031 In. (0.7 to 0.8 mm) Always use a

spark plug wrench.

Daily

1. Check engine oil level, and fill as necessary.

2. Check gasoline level, and fill as necessary.

always follow the fueling procedure outlined earlier

in this manual.

First 20 hours

1. Change engine oil.

Every 100 hours

1. Change engine oil.

2. Clean the sediment cup.

3. Clean and re-gap the spark plug.

4. Clean the spark arrestor.

Weekly

1. Remove the air filter cover and clean the element. In

very dusty environments, check the filter daily. Replace

the element as needed. Replacement elements can be

purchased from your local Honda dealer.

Engine Operation and Service

1. Clean and oil air filter pad on gasoline engine every 25

hours or once weekly. Do not permit the air intake screen

around the fly wheel of the gas engine to load up with

paint or trash. Clean it regularly. The service life and

efficiency of the gas engine model depends upon keeping

the gasoline engine running properly. Change the oil

in the engine every 100 hours. Failure to observe this

may result in engine overheating. Consult the engine

manufacturer’s service manual provided.

2. To conserve fuel, service life, and efficiency of the sprayer,

always operate the gasoline engine at the lowest RPM

at which it runs smoothly without laboring and delivers

the amount required for the particular painting operation.

Higher RPM does not produce higher working pressure.

The gasoline engine is connected to the hydraulic pump

by a pulley combination designed to produce full paint

delivery at maximum RPM.

3. The warranty on gasoline engines or electric motors is

limited to the original manufacturer.