26

maintenance

PowrBeast

7.8

SerVIcINg The hyDrAulIc moTor

Attention

Servicing of the hydraulic motor should be carried

out in a clean, dust free area only. Any dust or

metallic particles left in the motor or entering

it on reassembly may damage the critical parts

and affect its service life and warranty. All parts

should be inspected for absolute cleanliness.

i

In order to service the hydraulic motor, it is

recommended that the piston be set in the

middle of its stroke. Follow the steps below.

1. Turn the pressure control knob all the way counterclockwise

to the lowest setting.

2. With the fluid section submersed in a bucket of water, start

the engine or turn on the electric motor.

3. Turn the pressure control knob clockwise 1-2 full turns.

4. Once the pump is primed, turn the relief valve to SPRAy.

5. While watching the piston stroke from the window on the

back side of the motor/pump and using the smallest tip

available (for slowest piston speed possible), spray water

back in to the bucket (or other waste container). Stop

spraying when the piston is in the desired location.

6. Turn off the engine or electric motor.

7. Continue by following the steps below.

DISASSemBlINg The hyDrAulIc moTor

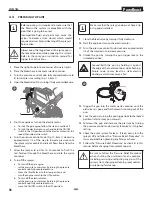

1. using a hex wrench, loosen the captive screws that secure

the PCB board assembly (Fig. 23, item 1) to the hydraulic

motor cylinder. Once removed, the board can hang by its

cord.

2. Remove the cylinder head plug (2) from the hydraulic

motor cylinder.

2

1

3. using a syringe or sponge, soak up any excess hydraulic

fluid in the cavity left by removing the cylinder head plug.

4. In the access area left by the removal of the PCB board

assembly, locate the flats on the bottom of the hydraulic

piston (Fig. 24, item 3). Place a wrench on the hydraulic

piston flats.

5. Slide the retaining ring (4) on the piston coupler (5) up to

clear it of the coupler holes.

6. Carefully insert a screwdriver into one of the open holes of

the piston coupler (5) to secure it.

i

you may need to twist the entire hydraulic piston

(4) and coupler (5) assembly slightly with the

wrench to gain access to one of the open holes.

7. Loosen the hydraulic piston (4) from the coupler (5) using

the wrench on the flats of the hydraulic piston (4).

4

5

3

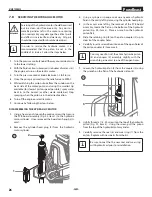

8. Lightly thread a 1/4 - 20 screw into the top of the hydraulic

piston (Fig. 25, item 4). using the screw, pull the piston

from the top of the hydraulic motor cylinder.

9. Carefully remove the seal (6) and wear ring (7) from the

piston. Replace with new parts from the kit.

i

Be sure to coat the the new seal and wear ring

with hydraulic oil prior to reinstallation.