TIMBERWOLF

TW PTO 150H

9

OPERATING INSTRUCTIONS

DAILY CHECKS BEFORE STARTING THE TRACTOR

CHECK chipper is securely and correctly mounted to 3 - point linkage.

CHECK chipper linkage for signs of damage or fatigue.

ENSURE drive shaft ends are securely fitted to PTO shaft and chipper input shaft.

CHECK for properly guarded PTO shaft, chipper input shaft and drive shaft.

CHECK that guard chains are securely attached to stationary frame to prevent rotation of guard.

CONNECT power cable from tractor to chipper.

LOCATE the machine on firm level ground.

CHECK chipper hydraulic oil level.

CHECK the discharge unit is in place and tightened securely.

CHECK discharge tube is pointing in a safe direction.

CHECK the feed funnel to ensure no objects are inside.

CHECK feed tray is in up position to prevent people reaching rollers.

CHECK controls as described below.

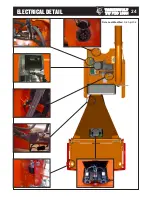

For parts location

see diagrams on

pages 3 & 4

IT IS ESSENTIAL TO CARRY OUT THE FOLLOWING TESTS

to check safety equipment - this sequence

of tests will only take a few seconds to carry out. We recommend that these tests are carried out daily.

Observing the function as described will confirm that the safety circuits are working correctly. This is also

a good opportunity to remind all operators of the control and emergency stop systems.

5

8

6

7

9

1

2

PRESS THE

GREEN BUTTON

THE ROLLERS

SHOULD TURN

FORWARDS

PRESS THE RED

SAFETY BAR

THE ROLLERS

SHOULD STOP

PRESS THE BLUE BUTTON

THE ROLLERS SHOULD TURN

BACKWARDS ONLY WHILE

THE BUTTON IS PRESSED

PRESS THE EMERGENCY

RED BUTTON

THE ROLLERS

SHOULD STOP

PRESS THE BLUE

BUTTON

THE ROLLERS

SHOULD NOT TURN

WITH THE ROTOR RUNNING AT 540 RPM

3

PRESS THE GREEN BUT-

TON

THE ROLLERS SHOULD

TURN FORWARDS

4

PULL THE RED

SAFETY BAR

THE ROLLERS

SHOULD STOP

PULL TO RESET THE RED BUTTON

WHILE PUSHING THE SAFETY BAR,

PRESS THE BLUE BUTTON.

ROLLERS SHOULD TURN BACKWARDS

ONLY WHILE BLUE BUTTON IS PRESSED

PRESS THE GREEN BUT-

TON AGAIN

THE ROLLERS SHOULD

TURN FORWARDS

BEFORE USING THE CHIPPER

This is situated on the side of the hydraulic oil tank. When the chipper is running

the oil temperature should not exceed 65

o

C. If it does, stop the machine

immediately. Failure to do so may result in damage. Overheating can result from

the chipper being worked extremely hard in hot conditions, as the oil is not getting

a chance to cool down. Stop the chipper and allow oil to cool before continuing.

If the temperature goes above 65

o

C and the machine is not being worked hard or

the air temperature is not particularly high this indicates low oil, a jammed hydraulic

motor or valve. Stop immediately and investigate.

HYDRAULIC OIL THERMOMETER / OIL LEVEL INDICATOR

When the chipper is on level ground the oil level should sit between the red line at the bottom of the

gauge and the blue line at the top. If this level drops significantly it indicates an oil leak. Stop

immediately and investigate.