Tiger Chipper Shredder CS7-200H & CS7-270H Owners Manual (PART CS-M)

page 9

the chipper and should be 45°. If you are unable to re

-

sharpen the blades yourself, either contact a professional

saw doctor. Normally only a slight touch up is needed. In this way your blades should last for a long time.

Remount the chipper blades including the blade shims, making sure that all mounting surfaces are cleaned

beforehand. Use Thread locker 269 Loctite on the bolts and torque to 25 ft

-

lb.

The clearance between the blade and anvil should be 2mm. Then turn the rotor by hand and check if the rotor turns

freely.

WARNING! Do not operate your chipper with blunt blades. This will cause excessive vibration which

may result in damage to the machine.

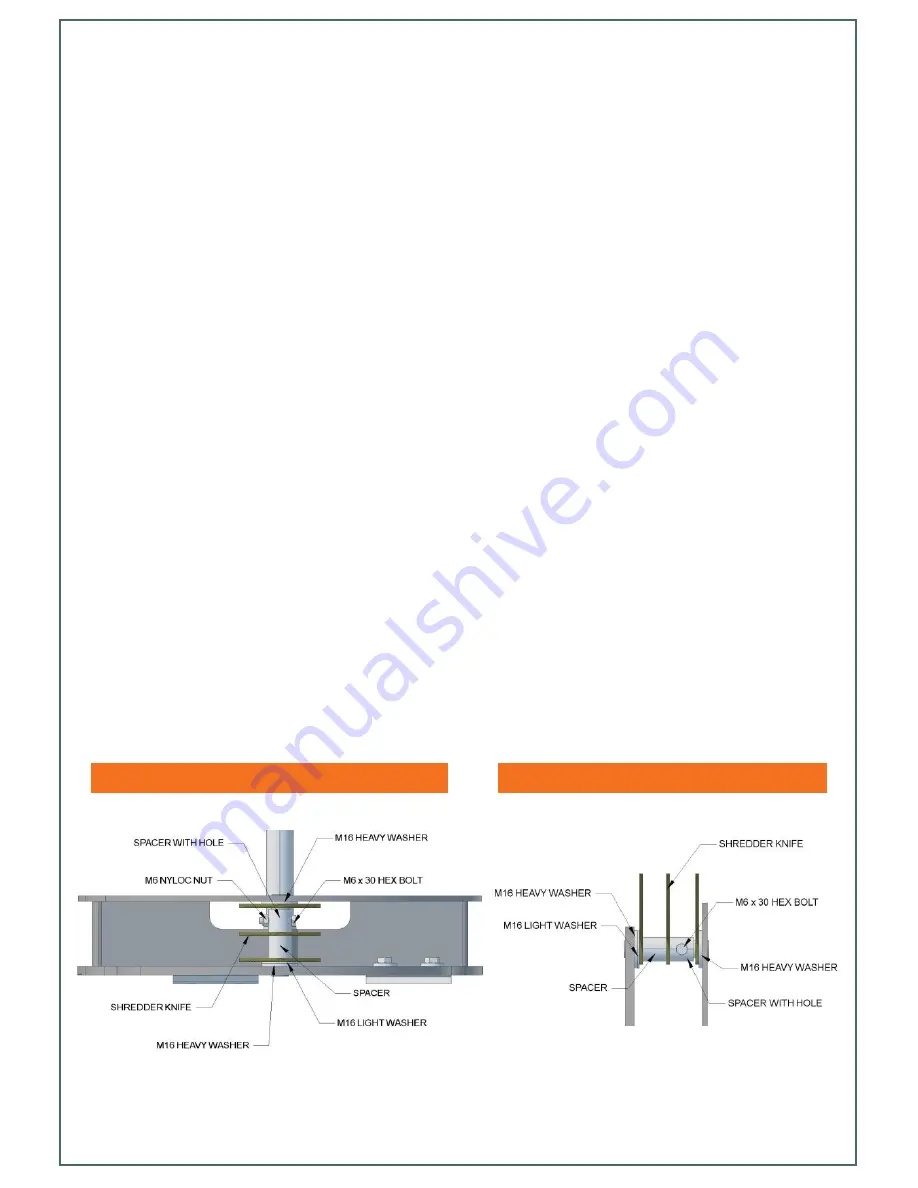

Shredder Knife Maintenance

Inspect the shredder knives for edge damage. If damaged the knives can be turned around to present a new edge,

if this has not been done previously. If both edges on the knives are used, replace the knives.

Remove M6 x 30 bolt and nyloc nut. Turn or replace knife.

WARNING! It is critical to maintain rotor balance, so replace knives in a set and ensure all spacers and

washers are replaced in their correct position. Always replace M6 x 30 bolts and nyloc nuts with new

ones. Do not reuse them.

Anvil Adjustment

The anvil is reversible, and can be used on all four edges. Normally the edges will last for a long time. When the

edge is rounded off, it can be reversed. When all edges are worn, the anvil can be sharpened or replaced.

The clearance between the blade and anvil should be 2mm. A piece of cardboard of the right thickness is usually a

good gauge for resetting the anvil. Always ensure these bolts are properly tightened to 95 ft

-

lb.

If there is not enough clearance, the blade edge may touch the anvil through deflection when cutting heavy

branches and damage the sharp edge. Too much clearance will allow small twigs and fibrous materials to be

dragged through without being cut.

Plan View: Rotor & Shredder Knife Setup

Side View: Rotor & Shredder Knife Setup