FLX

TM

Self-Regulating

4

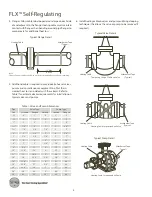

Table 1: Valve and Pump Allowances

Heating Cable

12” Max.

(30 cm)

Note:

Flange allowance will vary based on method of insulating flange and adjacent piping.

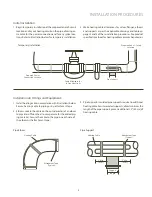

4. Flanges: Allow cable to be looped around pipe on each side

of and adjacent to the flange. Heating cable must maintain

contact with flange when bending around pipe flanges to

compensate for additional heat loss.

Attachment Tape

(Typical)

Heating Cable

Temporary Loop of Cable on Valve

Attachment Tape

(Typical)

Heating Cable Serpentined on Pump

Heating Cable

Attachment Tape

(Typical)

Heating Cable Serpentined on Valve

Typical Pump Detail

Heating Cable

Attachment Tape

(Typical)

Pipe

Size

Valve Type

Screwed Flanged Welded

Pump Type

Screwed Flanged

½"

6"

1'

0

1'

2'

¾"

9"

1'-6"

0

1'-6"

3'

1"

1'

2'

1'

2'

4'

1¼"

1'-6"

2'

1'

3'

4'-6"

1½"

1'-6"

2'-6"

1'-6"

3'

5'

2"

2'

2'-6"

2'

4'

5'-6"

3"

2'-6"

3'-6"

2'-6"

5'

7'

4"

4'

5'

3'

8'

10'

6"

7'

8'

3'-6"

14'

16'

8"

9'-6"

11'

4'

19'

22'

10"

12'-6"

14'

4'

25'

28'

12"

15'

16'-6"

5'

30'

33'

14"

18'

19'-6"

5'-6"

36'

39'

16"

21'-6"

23'

6'

43'

46'

18"

25'-6"

27'

6'-6"

51'

54'

20"

28'-6"

30'

7'

57'

60'

24"

34'

36'

8'

68'

72'

30"

40'

42'

10'

80'

84'

6. Install heating cable on valves and pumps utilizing a looping

technique (this allows the valve or pump to be removed if

required).

5. Additional cable is required to provide extra heat at valves,

pumps and miscellaneous equipment to offset the in-

creased heat loss associated with these items. Refer to

Table 1 for estimated cable requirements for installation on

typical valves and pumps.

Typical Valve Details

Typical Flange Detail