22

..... Additional setup menus within the OPTIONS submenu

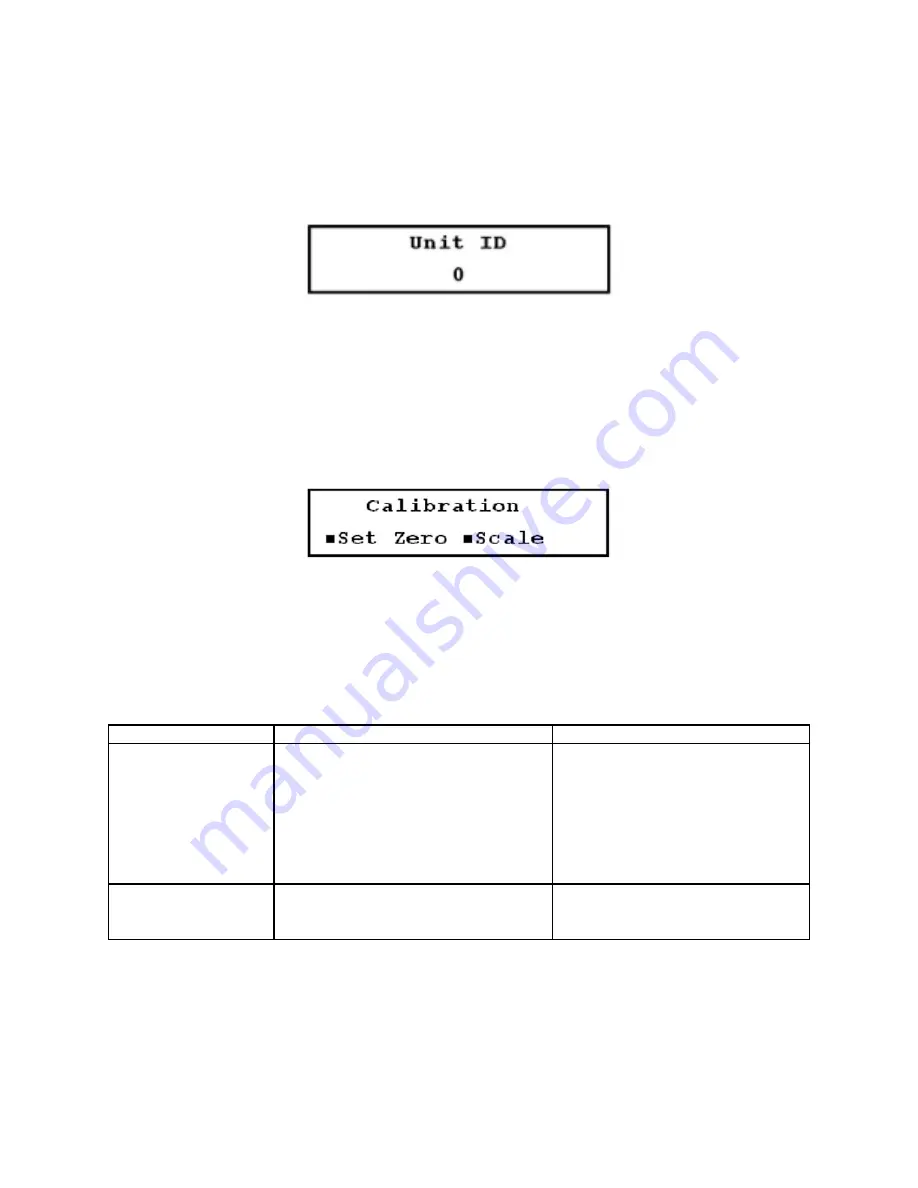

6.

Unit ID (identification) Number

setup menu (49): This number is determined by the operator to identify

the specific instrument or site. Any whole number between 1 and 60,000 may be entered

(Figure 3.12-N, below).

F

IGURE

3.12-N

3.13 Additional Setup Menus Within the CALIBR Submenu

*Not included in the Quick Setup configuration

Within the

CALIBR

submenu is the

Calibration Group

menu (50) (Figure 3.13-A, below), which contains 4

setup menus:

Zero Set, Scale, SS Comp, Date

(Menus 51 through 54).

F

IGURE

3.13-A

3.13.1 Zero Set Calibration

An important step in assuring accurate flow measurement is the proper calibration of the instrument and

proper installation. The calibration methods must be performed for the particular pipe that is to be metered.

Table 3 (below) provides guidelines for selecting a calibration method.

Calibration Method

Function

Application

Zero set calibration

Zero flow set

Zeroes the instrument for an actual no

Installations where flow can be

flow condition

stopped

Manual zero set

Applies a manually entered offset to

Where an offset is required

all flow readings

Scale factor

Compensates for manufacturing

Set by the factory to the value

variations in the transducers

imprinted on the transducers

T

ABLE

3

After installing the meter, you may find that a small adjustment to the zero point (zero set calibration) is

required. Zero set calibration allows the meter to read very close to zero under zero flow conditions. There

are two zero set calibration methods in Menu 51: the zero flow set method and the manual zero set

method. View the zero point used by the flowmeter in either of these methods by selecting

Manual

in Menu

51.