37

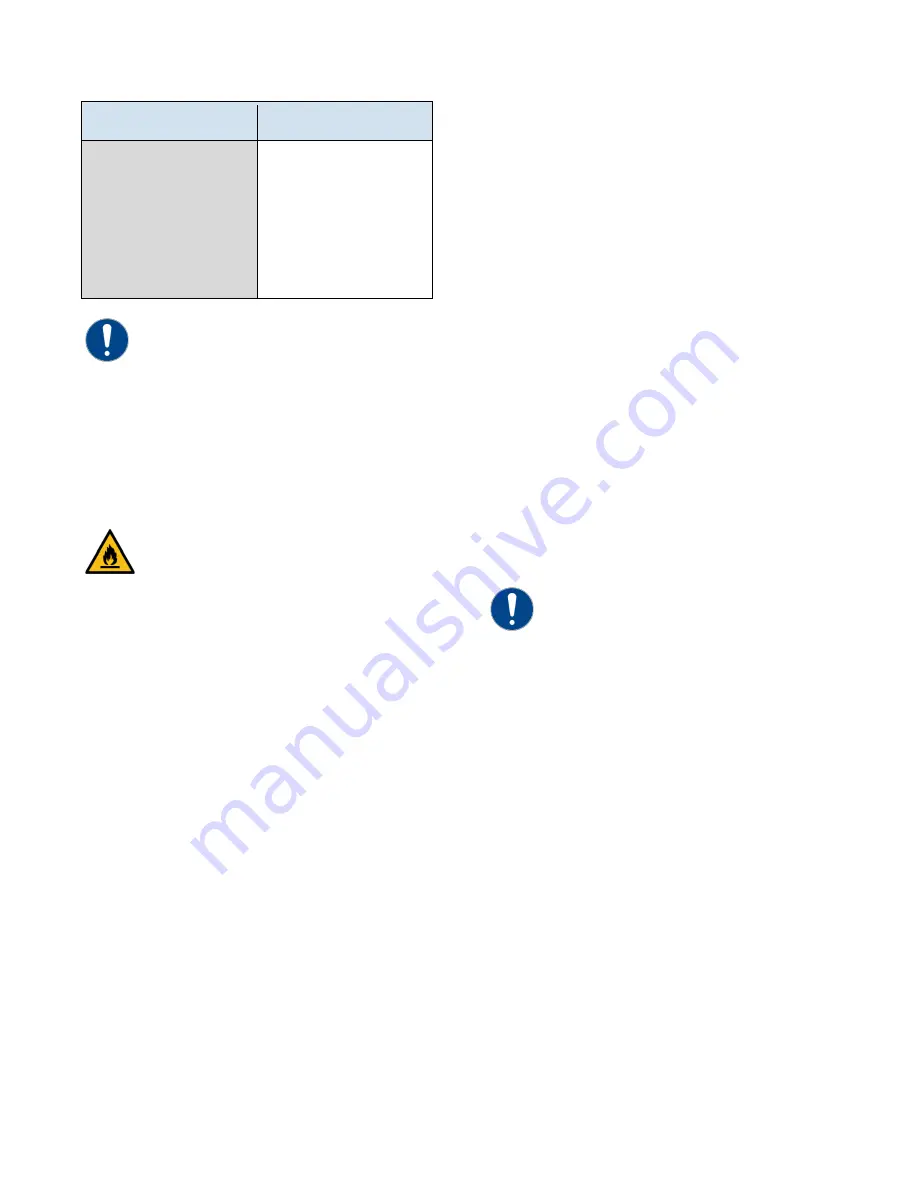

Table 20 - Recommended Glycol Solutions

Chilled Water

Temperature

Percent Glycol

By Volume

50°F (10°C)

Not required

45°F (7.2°C)

5 %

40°F (4.4°C)

10 %

35°F (1.7°C)

15 %

30°F (-1.1°C)

20 %

25°F (-3.9°C)

25 %

20°F (-6.7°C)

30 %

CAUTION: When your application requires the use of

glycol, use industrial grade glycol specifically designed

for heat transfer systems and equipment. Never use

glycol designed for automotive applications.

Automotive glycols typically have additives engineered

to benefit the materials and conditions found in an

automotive engine; however, these additives can gel

and foul heat exchange surfaces and result in loss of

performance or even failure of the chiller. In addition,

these additives can react with the materials of the

pump shaft seals resulting in leaks or premature pump

failures.

WARNING: Ethylene Glycol is flammable at higher

temperatures in a vapor state. Carefully handle this

material and keep away from open flames or other

possible ignition sources.

Step 3 - Check Condenser

There are two possible types of condensers present

in the chiller: water-cooled and remote air-cooled. It

is important to verify the chiller will have adequate

condenser cooling for proper chiller operation.

Water-Cooled Condenser Check

Check the condenser water lines to make sure all

connections are secure. Make sure sufficient

condenser water flow and pressure are available, the

condenser water supply is on, and all shut-off valves

are open. The electronic water regulating valves ship

in the closed position and opens after enabling the

circuit.

Remote Air-Cooled Condenser Check

Check the refrigerant lines to make sure all

connections are secure and the refrigeration is as

described in the installation section of this manual.

Check the remote condenser main power and

control wiring to ensure all connections are secure.

Step 4 – Check Refrigerant Valves

During shipment or installation it is possibe valves

were closed. Verify that all refrigerant valves are

open.

Step 5 – Check Low Temperature Alarm

Make sure the Low Temperature Alarm Set Point is

set appropriately for the operating conditions of the

chiller. The Low Temperature Alarm setting is in a

password protected menu of the chiller controller.

Refer to the control section of this manual for

instructions on how to access this menu. The Low

Temperature Alarm should be set at 10°F below the

minimum chilled water temperature setting that the

chiller will be operating. Also ensure the process

coolant has sufficient freeze protection (glycol) to

handle at least 5°F below the Low Temperature

Alarm setting. All chillers are shipped from the

factory with the Low Temperature Alarm set at 35°F.

This is done to protect against a possible freeze-up if

no glycol has been added to the coolant. Once the

proper glycol solution has been added, the Low

Temperature Alarm can be adjusted to the

appropriate setting.

CAUTION: The manufacturer’s warranty does not

cover the evaporator from freezing. It is vital that the

Freezestat is set properly.

Step 6 – Turn On Control Power

Turn on the control power by turning the control

power switch to "On". The panel displays should now

be illuminated. Due to extreme ambient

temperatures that the unit may be exposed to

during shipment and installation, you may encounter

a High Refrigerant Pressure alarm when you turn on

the control power. If this is the case, reset the alarm.

Do not proceed until all alarms have been reset and

no further alarm conditions are present.