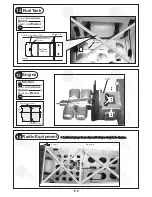

Apply thread locker

P. 3 -14

Do not overlook this symbol!

Cut off shaded portion.

Peel off shaded portion

covering film.

Pay close attention here!

Pierce the shaded portion

covering film.

Must be purchased separately!

Drill holes with the specified

diameter (here: 3mm).

3mm

I N D E X

BEFORE YOU BEGIN

PARTS LIST

ASSEMBLY

SAFETY PRECAUTIONS

P. 1

P. 2

P. 14

BEFORE YOU BEGIN

Read through the manual before you begin

,

so you will have an overall idea of what to do.

Symbols used throughout this instruction manual comprise of the following : -

Ensure smooth non-binding

movement while assembling.

Apply instant glue

(C.A.glue, super glue.)

Assemble left and right

sides the same way.

Apply epoxy glue.

1

2

3

P.1

Check all parts. If you find any defective or missing parts contact your local dealer. Please DRY FIT

and check for defects for all parts that will require CA or Epoxy for final assembly. Any parts you

find to be defective after the gluing process may be difficult to remove for warranty replacement. The

manufacturer will replace any defective parts. but will not extend to the parts that are good before

gluing to defective parts during assembly. Warranty

will

not

cover

any

parts

modified

by

customer

.