©Copyright Task Force Tips LLC 2014-2021

21

LIA-208 May 19, 2021 Rev05

8.4 CRANKSHAFT OVERRIDE AND REPLACEMENT

The crankshaft includes an intentional shear joint to protect the gear train from overload, costly repairs, and loss of service. The

magnitude of torque required to shear the crankshaft is several times greater than the torque typically needed to operate the valve at

maximum operating pressure. If the crankshaft breaks during use, this is an indication that either there is something obstructing the half

ball internally. or the crank shaft has been abused (e.g. used as a step for climbing).

8.4.1 EMERGENCY CRANKSHAFT OVERRIDE

In an emergency, the opposite side of the crankshaft can be turned using a 1/2” wrench or hex socket. This allows the valve to be open

or closed until the crankshaft is replaced. To prevent loss of the 1/8” square key on the crankshaft, do not allow the crankshaft to slide

out of gearbox until a replacement crankshaft is on hand. It is important not to rely on the emergency override as a long-term method of

operation.

8.4.2 DIAGNOSING CRANKSHAFT FAILURE

To determine the cause of a crankshaft to failure, complete the following steps:

1. Close upstream water supply. If possible, relieve pressure leading up to valve.

2. Locate 1/2” hex where crankshaft protrudes from opposite side of gearbox.

3. Gently turn crank shaft away from travel stop using a ½” hex wrench. Do not attempt to shock crankshaft free and do not exceed

50 ft-lb (68 Nm) of torque.

4.

If crankshaft will not rotate

, half ball is likely obstructed. Only after relieving pressure on flanged joint, unbolt valve. Clear any

obstructions and evaluate whether repair is needed before returning to service.

5.

If crankshaft is able to rotate

, cycle the valve several times from open to closed to determine whether the crankshaft binds at

any place between the travel stops. If crankshaft binds, consult Task Force Tips Service Department to determine the appropriate

repairs.

6.

If crankshaft rotates freely after clearing any obstructions

, a replacement crank shaft may be ordered from Task Force Tips

and replaced as described below.

8.4.3 CRANKSHAFT REPLACEMENT

A broken crankshaft can be replaced at any time by completing the following steps, regardless of whether or not the upstream water

supply is pressurized. Referring to item numbers shown in the exploded view available at TFT.com/serial-number, follow the steps

below:

1. Remove external retaining ring (item 118) adjacent to ½” hex on crankshaft. Do not over-expand the retaining ring.

2. Using a punch or Phillips head screwdriver at least 6” in length, gently push on dimple in ½” hex end of crankshaft (item 131).

Continue to push crankshaft through until it protrudes from opposite side of gearbox.

3. Grab broken end of crankshaft and pull out of gearbox. As crankshaft is withdrawn, grasp small key (item 119) on shaft so it does

not get lost.

B. If 1/8” square x 1” long key is not visible in shaft, it has likely fallen into gearbox bore and must be removed before installing

new crankshaft. If square key is visible in gearbox bore, slide it out of bore. Needle-nose pliers may be helpful depending on

position of key in bore.

4. Verify polymer bushings (item 117 and 120) are still seated in bores on each side of gearbox. If not, locate and reinstall bushings.

5. Look through gearbox bore and note approximate orientation of square keyway in worm (item 115). Verify round notch in thrust

washer (item 116) is aligned with square keyway in worm.

6. Prepare new crankshaft by applying small dab of grease to keyway and seating 1/8” square x 1” long key into keyway. Grease will

keep key in place during assembly.

7. Slide shaft into gearbox with key orientation the same as keyway in worm.

8. Rotate shaft slightly in alternating directions until key finds keyway, then push shaft in until it stops. Retaining ring groove and ½”

hex should be protruding through opposite side of gearbox.

A. If hex is not visible, it may be necessary to slide polymer bushing back into gearbox bore.

9. Install retaining ring (item 118) onto shaft. Do not over-expand the retaining ring.

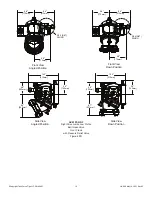

Figure 8.4.3

115

116

117

118

120

119

131

116