1802 Bending Table

Greenlee / A Textron Company

4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

6

Select the proper size pipe support pins to be used:

• 3/4" diameter pin with 880 bender

• 1" diameter pin with 777 and 883 benders

• 1-1/2" diameter pin with 884 and 885 benders

Pipe support pin “A” is placed in bender frame hole that

corresponds to the size of conduit to be bent. Place

bender on table bed near end, opposite idler gear. Move

chain crank bracket forward to match the conduit size

holes in frame with like holes in bender bracket. Insert

pipe support pin “B” into brackets, bender frame, and

pipe support. When fully assembled, pipe support pin

“A” should be approximately 1" from leg support.

Note: Pipe support pins are optional equipment with

this unit and not furnished by the manufacturer.

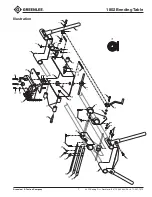

Attach loose end of drive chain to pipe vise unit. Then

place chain around idler gear and chain crank gear.

Reposition idler gear to tighten drive chain, as it must be

tight for proper operation. Bending table is now ready

for bending radii up to 36" and with the Greenlee 884 or

885 bender in outer pipe support holes.

Note: To bend 36" radii or larger, chain extension kit

50214136 must be added to the standard drive chain.

This kit is required when using Greenlee 777 and 880

benders in the outer most position and Greenlee 884

and 885 benders in 3" pipe support position and lower.

Chain Crank

Pipe Vise

Idler Gear

Pipe Support

Pin “A”

Pipe Support

Pin “B”

Chain Crank Unit

Bender

Pipe Support

Bender

Bracket

Setup

(cont’d)

Figure 6

Figure 7

CHECK ALL SCREWS TO BE SURE THEY ARE TIGHT.

In some instances, when extra long radii bends are required, the length of bending table

at left end can be extended by adding 24" conduit couplings.