6 Firmware and GUI Application

The DRV8316xEVM can implement sensored, sensorless, or Field-oriented control for commutating a three-

phase Brushless-DC motor. The supported firmware is a sensorless ield-oriented control algorithm adapted from

Texas Instruments’ MotorControl SDK Library of motor solutions. The algorithm includes motor identification and

parameters, sensorless sinusoidal commutation, torque and speed control, and field weakening to maximize

the performance of the motor. The firmware uses GUI Composer to run the algorithm and includes a tab to

read/write to the DRV8316 SPI registers.

The following steps describe how to identify useful motor parameters, spin the motor using a sensorless

sinusoidal profile, use the PI controller gain settings for torque and speed control, and communicate with the

DRV8316 SPI registers. For more information on advanced features of the C2000 InstaSPIN Universal GUI such

as MTPA or Field-weakening , consult the MotorControl SDK InstaSPIN Lab Guide (in the

InstaSPIN-FOC and InstaSPIN-MOTION User’s Guide

6.1 C2000

™

InstaSPIN

™

Universal GUI

and ensure the LAUNCHXL-F280049C is connected to

the PC and the power supply is turned on to the DRV8316xEVM PCB.

2. Access the

GUI Composer Gallery

"DRV8316xEVM_InstaSPIN_Universal_GUI". Click on the GUI.

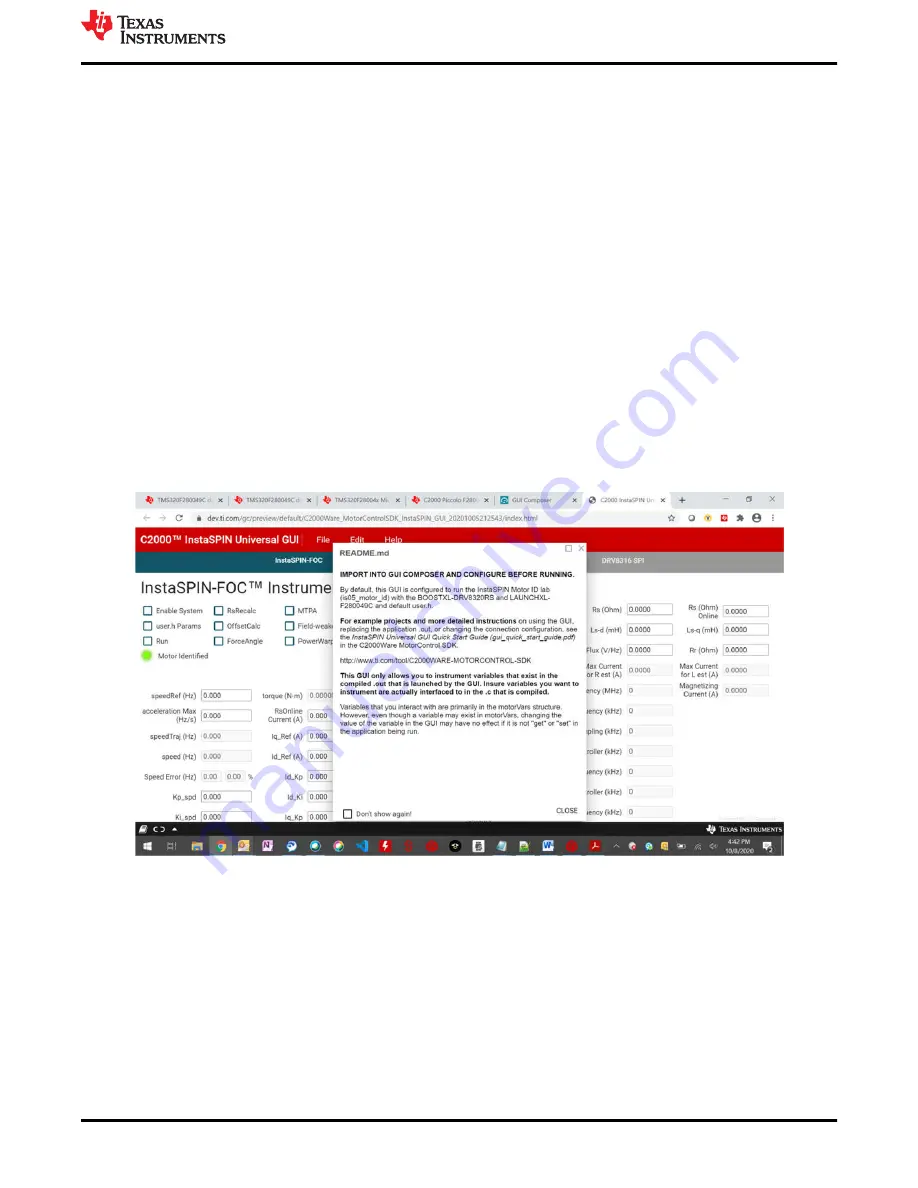

3. Accept the readme as shown in

and check the bottom left hand corner of the screen for

“Hardware Connected”. Once connected, the GUI will flash the algorithm to the MCU as shown in

Figure 6-1. C2000

™

InstaSPIN

™

Universal GUI for DRV8316xEVM

Firmware and GUI Application

SLVUBZ9B – DECEMBER 2020 – REVISED AUGUST 2021

DRV8316xEVM Evaluation Module

19

Copyright © 2021 Texas Instruments Incorporated