FF-MM-31-REV - 00

Page 4

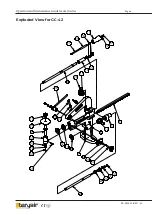

Operation and Maintenance Guide Gasket Cutter

B) STEPS TO CUT IRREGULAR

SHAPED GASKET

Step 1 -

Cut out approximate raw size of gasket

from oil.

Step 2 -

Mark the required irregular shape on

gasket.

Step 3 -

Lift the upper cutter disc (8) of the

machine by using its cam lever (18)

Step 4 -

Loosen lock screw (32) and slide

moveable scale (5) so that pivot arm (35) does

not obstruct the cutting action , or if gasket to

be cut is rather big enough, let the pivot pin

support the gasket from bottom.

Step 5 -

Bring the marked line on the gasket

below cutting edge of the upper cutter disc (8)

Step 6 -

Lower the upper cutter disc (8) by

operating cam lever (18) So that the cutter bites

in the gasket on marked line.

Step 7 -

Hold the handle (15) and start rotating

it ,so that the gasket moves. Hold the gasket and

feed it along the markings below the upper

cutter disc (8) The cutter will cut the gasket

along the marking , as long as handle is rotated

Step 8 -

Stop rotating the handle after desired

shape of gasket is fully cut.

Oil holes are provided at front side, in spindle

front bush (2) Spindle rear bush (3) and in

pivotarm (35)

1. For smooth functioning sufficient oil drops

should be put through the oil holes and in

gears ( 10,11) after and before use.

2. Clean the machine near cutting area and

rotating parts after some use

3. Re - Sharpen the cutter on any bench

grinder taking care that cutting edge of the

cutter is not damaged or flattened.

Maintenance