CAUTION : Please cut electrical connection of your product at

all kind of maintenance operations.

Follow circuit diagrams for a new connection. Earth connection

must be done to connection terminal (terminal signed by earth

symbol.)

SECTION 4

USAGE of CERAMIC COOKER

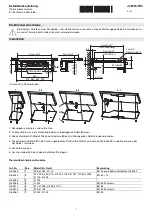

You can find control buttons in Figure 5. With these control buttons

power of each heating element can be adjustable. Buttons can turn

clolckwise or opposite to clockwise directions.

Please bring the control button to required cooking position and do

not forget big numbers on button print means high heat outlet. For first

cooking, it recommended to use highest cooking position.

Figure 5

SECTION 5 MAINTENANCE & CLEANING

Before start cleaning cooker be sure that electrical connection is cut

off. Please do not use rough pots can scratch the surface of cooker.

Before using cooking pots, pay attention that their base is dry and

clean. Base diameter of cooking pots must be same as cooking

surface of cooker. Base of cooking pot must be a little concave in cold

condition. When this concave base heated, its contact with cooker

surface increases by expantion; so maximum heat transfer from cooker

to pot provided. Best base thickness for enamelled pots is 2-3 mm.

For sandwich type stainless steel pots 4-6 mm base thickness is

recommended.

To test whether pot base has right shape or not, you can do this easy

test when t is cold as follows : Let pot base stay contacted to smooth

side of desk in right, pass it on between some paper tape. ( For

enamelled pot 5-10 pieces of paper tape, for stainless steel pot 2-5

pieces of tape are recommended.)

NOTICE :

Please cut off electricity at the moment of any crack formed

on surface of ceramic cooker.

Ceramic cookers are easy cleaning appliances

Firstly all food and oil churns lightly cleaned with a glass scraper

without scratching. Soft razor mouthed type or fixed razor side can be

used as a glass scraper.

4

3

4

1

2

0

3

6

5

5

2

2

0

1

4

3

5

6

4

0

1

3

2

6

5

1

0

6

CAUTION : Please cut electrical connection of your product at

all kind of maintenance operations.

Follow circuit diagrams for a new connection. Earth connection

must be done to connection terminal (terminal signed by earth

symbol.)

SECTION 4

USAGE of CERAMIC COOKER

You can find control buttons in Figure 5. With these control buttons

power of each heating element can be adjustable. Buttons can turn

clolckwise or opposite to clockwise directions.

Please bring the control button to required cooking position and do

not forget big numbers on button print means high heat outlet. For first

cooking, it recommended to use highest cooking position.

Figure 5

SECTION 5 MAINTENANCE & CLEANING

Before start cleaning cooker be sure that electrical connection is cut

off. Please do not use rough pots can scratch the surface of cooker.

Before using cooking pots, pay attention that their base is dry and

clean. Base diameter of cooking pots must be same as cooking

surface of cooker. Base of cooking pot must be a little concave in cold

condition. When this concave base heated, its contact with cooker

surface increases by expantion; so maximum heat transfer from cooker

to pot provided. Best base thickness for enamelled pots is 2-3 mm.

For sandwich type stainless steel pots 4-6 mm base thickness is

recommended.

To test whether pot base has right shape or not, you can do this easy

test when t is cold as follows : Let pot base stay contacted to smooth

side of desk in right, pass it on between some paper tape. ( For

enamelled pot 5-10 pieces of paper tape, for stainless steel pot 2-5

pieces of tape are recommended.)

NOTICE :

Please cut off electricity at the moment of any crack formed

on surface of ceramic cooker.

Ceramic cookers are easy cleaning appliances

Firstly all food and oil churns lightly cleaned with a glass scraper

without scratching. Soft razor mouthed type or fixed razor side can be

used as a glass scraper.

4

3

4

1

2

0

3

6

5

5

2

2

0

1

4

3

5

6

4

0

1

3

2

6

5

1

0

6