F) Repeat this test on Q5 as well using the differential probe.

if the signal is not present, there may be a fault in the IGBT

driver circuit (

).

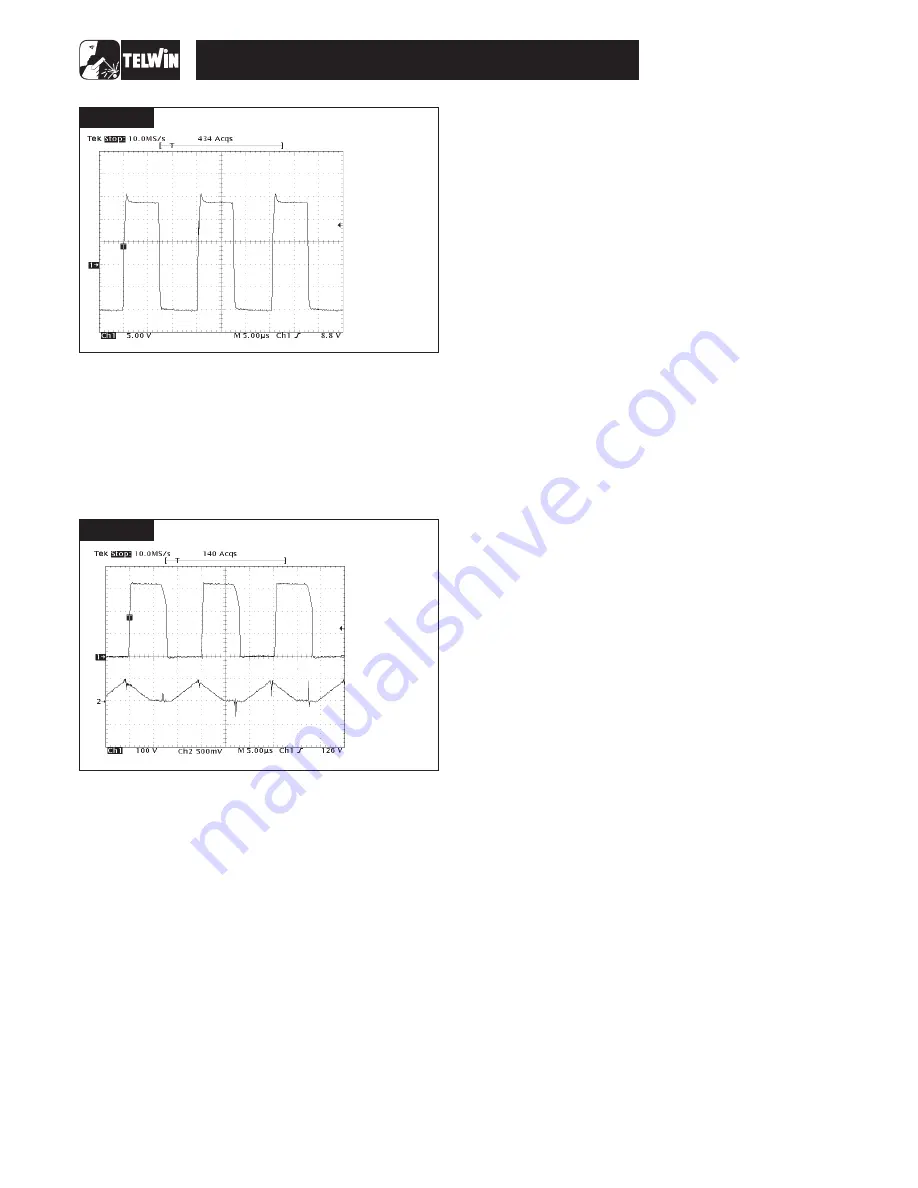

G) Set up the dual trace oscilloscope. Connect probe CH1

(x100) to the collector of Q8 and probe CH2 (x10) on

. The earth terminals are connected together to the emitter

of Q1.

H) Make sure the waveform displayed on the oscilloscope

resembles

and that the output voltage over OUT+ and

OUT - is equal to +75Vdc±10%.

I) Switch the power source on again and make sure that,

following the brief start up time, the machine is not in alarm

status (the yellow alarm LED D12 is off,

).

If the

machine remains in alarm status (and this is not due to a fault

in the control) there could be a fault in the photocoupler ISO1

(

).

If the fault is in the power board remove it from the bottom as

follows:

-

with the machine disconnected from the main supply,

disconnect all the wiring connected to the board;

-

remove the current adjustment knob on the front panel of

the machine (

);

-

remove any bands constraining the board (e.g. on the

power supply cable and connections to primary);

-

from the welding side undo the two screws fastening the

dinse sockets to the printed circuit board (

).

-

undo the 2 screws fastening the board to the bottom (

).

-

undo the 2 screws fastening the board to the front and back

on the inside (

).

-

after removing the screws, lift the board upwards to remove

it from the bottom of the machine.

to re-assemble, proceed in the reverse order,

remembering to insert the toothed washers on the earth

screws.

The 2 IGBT's are attached to 2 different dissipators and

whenever a replacement is required, both IGBT's should be

replaced.

-

undo the screws attaching the dissipator to the board to

replace IGBT (

);

-

undo the screws attaching the dissipator to the board to

replace IGBT(

);

-

remove the 2 IGBT's Q5,Q8 and the 2 diodes D14, D31 by

unsoldering the rheofores and then clean the solder from

the printed circuit bump contacts;

-

remove the 2 dissipators from the board;

-

undo the screws locking the 2 IGBT's.

Before making the replacement make sure the components

piloting the IGBT's are not also damaged:

-

with the multimeter set in

mode make sure there is no

short circuit on the PCB between the 1 and 3 bump

contacts (between gate and emitter) corresponding to each

component;

-

alternatively, resistors R54 and R61 could have burst

and/or diodes D16, D17, D29 and D30 may be unable to

function at the correct Zener voltage (this should have

shown up in the preliminary tests);

-

clean any irregularity or dirt from the dissipators. If the

IGBT's have burst the dissipators may have been

irreversibly damaged: in this case they should be replaced;

-

apply thermo-conductive grease following the general

instructions.

-

Insert the new IGBT's between the dissipator and the

spring, taking care not to damage the component during

assembly (the spring should be inserted under pressure on

the dissipator so as to lock the component);

-

place the dissipators with the new IGBT's and primary

diodes D14 and D20 (

Make sure there is

insulation between the case of diode D20 and the

dissipator) in the PCB bump contacts, placing 4 spacers

between the dissipator and the PCB (2 for each dissipator)

and fasten them down with the screws (torque wrench

setting for screws 1 Nm ±20%);

-

solder the terminals taking care not to let the solder run

along them;

N.B.

fig. 4

fig. C

fig. 3

N.B.

fig. 3

fig. 1

fig. 2B

fig.

2B

fig. 2B

N.B.

A) Please read the procedure for replacing the IGBT's

carefully: (fig. 4).

fig. 2B

fig. 2B

ohm

WARNING!

Test Point

XT5

7.1 Removing the power board fig. 2A

(

)

st

rd

6.3 Scheduled tests for the TECNICA 164

WARNING!

Warning:

In this case the tests are the exactly the same as

those for the Tecnica 144 and can be carried out in the same

way.

If repairing the board is complicated or impossible, it should be

completely replaced. The board is identified by a 6-digit code

(printed in white on the component side after the initials TW).

This is the reference code for requesting a replacement:

Telwin may supply boards that are compatible but with

different codes.

before inserting a new board check it carefully for

damage that may have occurred in transit. When we supply a

board it has already been tested and so if the fault is still

present after it has been replaced correctly, check the other

machine components. Unless specifically required by the

procedure, never alter the board trimmers.

7.0 Repairs, replacing the boards

- 12 -

SETTINGS CH1:

· PROBE x10;

· 5 V/Div;

· 5 sec/Div.

·

:

65KHz±10%;

· AMPLITUDE IS:

POSITIV ON CH1 IS

+15V ±10%;

· AMPLITUDE IS:

NEGATIV ON CH1 IS -

10V ±10%.

VERIFY THAT:

THE FREQUENCY IS

µ

FIGURE B

IMPOSTAZIONI:

- SONDA CH1 x100

- 100V/Div;

- SONDA CH2 x10;

- 500mV/Div;

- 5 sec/Div.

VERIFICARE CHE:

- L’AMPIEZZA SU CH1

SIA 320V ±10%;

- L’AMPIEZZA SU CH2

SIA 500mV ±10%.

µ

FIGURE C

TECNICA 144 - 164