CHAPTER 3

Maintenance

IMPORTANT:

The Airman 8 headset was designed, tested, and approved to FAA TSO C139a. The TSO

requires the headset meet the minimum performance specifications as defined in RTCA DO-

214a. This document and specifications listed here reference the test procedures and

equipment used as defined in these standards. Refer to the standard for details on how to

perform individual tests.

3.1

Troubleshoot and Maintenance

The Airman 8 headset is designed so that ANR performance and boom microphone sensitivity can be adjusted as

required to meet specification requirements. These are only adjustments that can be made to the headset in order to

alter performance. All other maintenance requires replacement of parts, fixing open wires, or removing shorted wires.

See specific instructions later in this section for ANR or boom microphone adjustment.

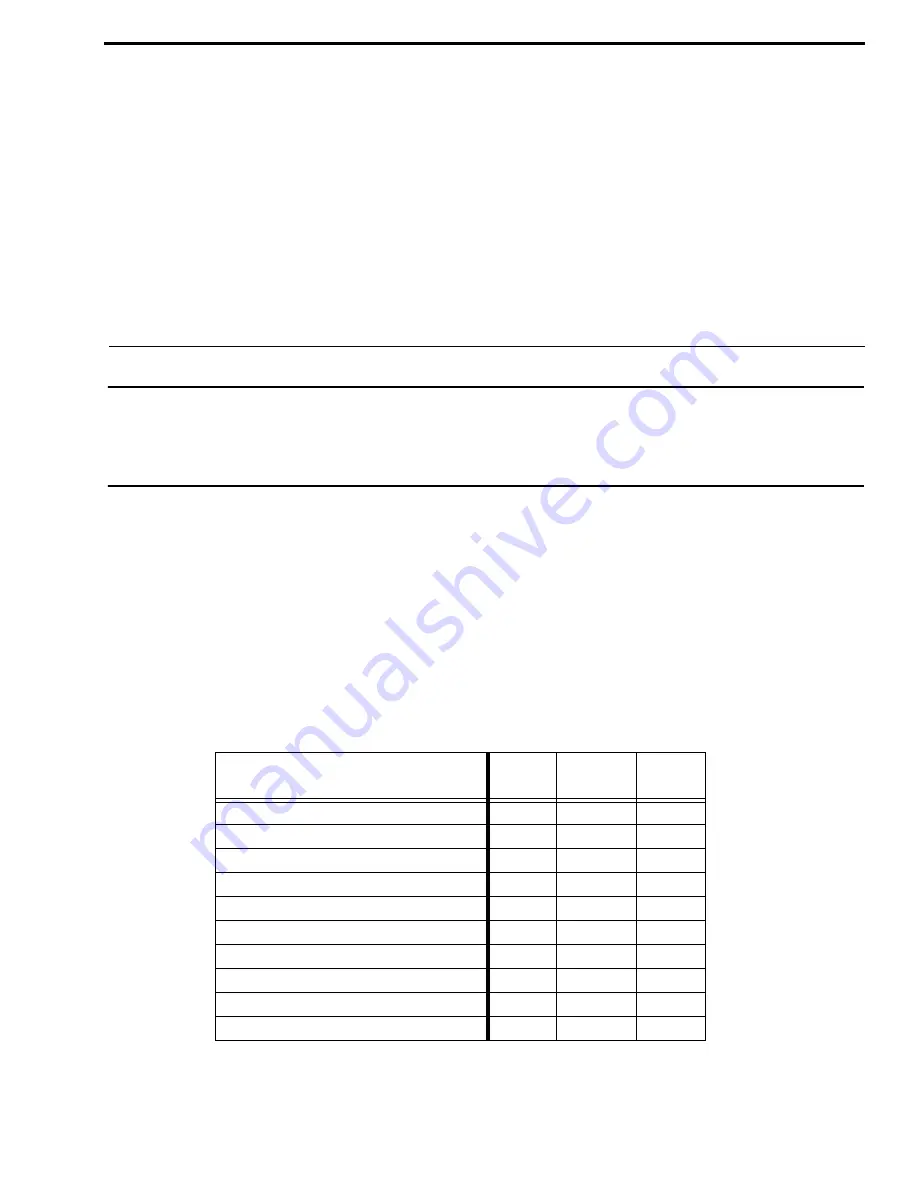

3.1.1 Recommended Maintenance Schedule

NOTE:

Ear cushions, headband pads, and microphone wind screens are considered wear items. For

proper headset performance, these items need to be inspected and replaced at regular intervals.

See the maintenance schedule below for more information. Headset performance diminishes if

items are not replaced when deterioration or damage is apparent.

Check Boom Mic Placement

X

Check Ear Cup Placement

X

Check Headband Fit

X

Inspect & Clean Connectors

X

Clean Ear Cushions

X

Clean Headband Pad

X

Check Connection Cable

X

Inspect & Replace Windscreen

X

Inspect & Replace Ear Cushions

X

Inspect & Replace Headband Pad

X

Task

Per

Use

Monthly

6

Months

Summary of Contents for Airman 8

Page 33: ...Airman 8 Parts List and Disassembly Assembly 33 5 Firmly press the headband pad into place...

Page 34: ...34 Parts List and Disassembly Assembly Airman 8...

Page 36: ...36 Maintenance Airman 8...

Page 38: ...38 Maintenance Airman 8...

Page 41: ...Airman 8 Maintenance 41 3 1 5 Speaker Troubleshooting and Workflow...

Page 43: ...Airman 8 Maintenance 43 3 1 6 ANR Troubleshooting and Workflow...

Page 48: ...48 Maintenance Airman 8...