30 Maintenance

Airman 750/760 CMM

4.2.1 Testing the Circuit Board Assembly

To

test the circuit board assembly

, do the following:

1. Construct the test circuit. For more information, see Figure 4.

2. Connect the

circuit board

to the test circuit.

3. Remove the circuit board and wiring completely from the headset.

4. Set Vin to measure 0.47 mVAC, 1Khz, V

OUT

should read 297-592 mV,

when pot is set to midpoint.

If the output is outside this range, replace the circuit board. Specifications apply with

SW1 in both normal and reverse positions.

4.3 Speaker Validation

4.3.1 Speaker Sensitivity and Frequency Response Verification

Transducer Type:

Dynamic

Sensitivity:

(All Models) 104dB SPL ±5dB at 1kHz, 1mW input to headset,

at LOW volume control setting.

1mW based on input impedance of headset being tested.

Frequency

Response:

Must meet standards outlined in the specifications.

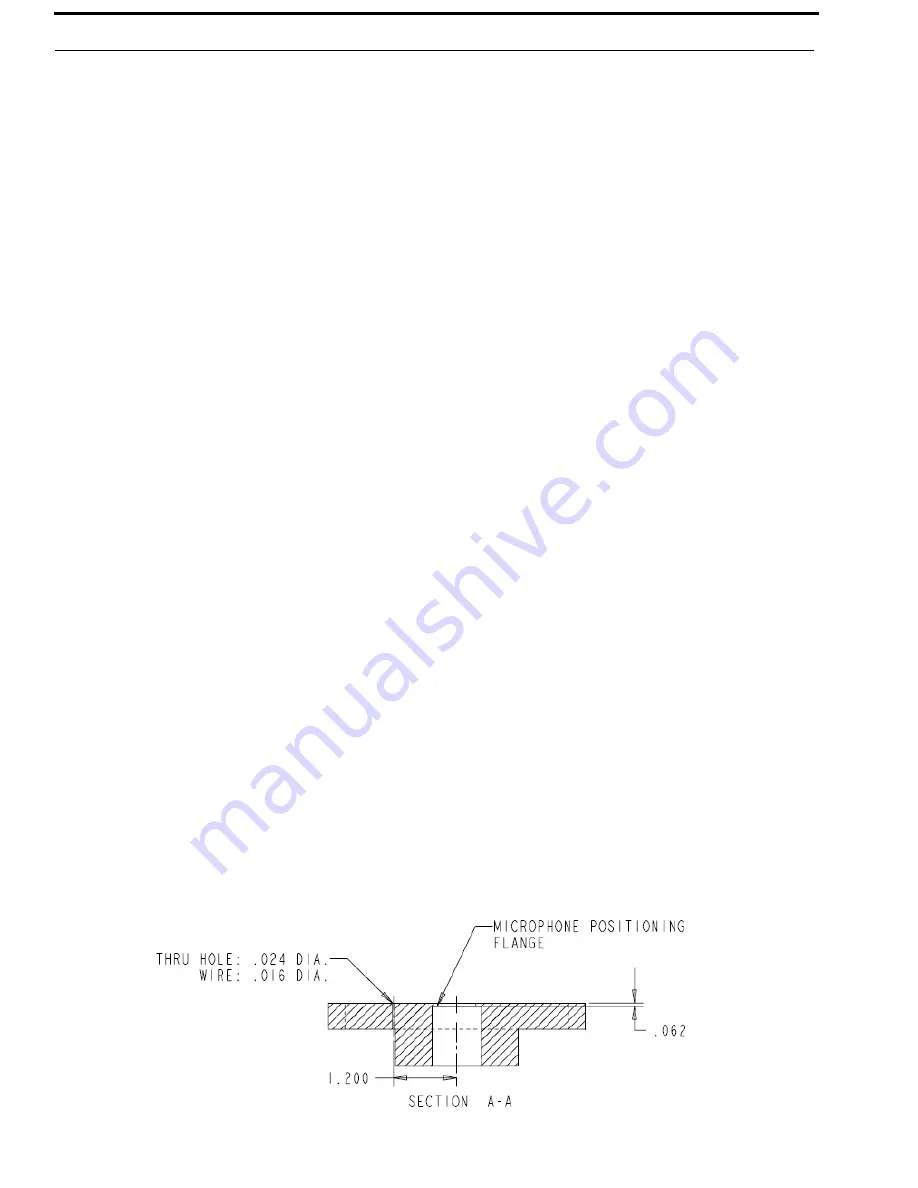

Earphone testing for the Airman 750 and 760 is done on a flat plate coupler.

For more information, see Figure 5.

To

measure the speaker

, do the following:

1. Calibrate a

lab microphone

.

2. Connect an

audio analyzer

to the lab microphone.

3. Place the

calibrated lab microphone

under the flat plate coupler and up through the

hole,

flush to the microphone positioning flange. (Use wire?) See Figure 5.

4. Place the

speaker (without the foam ear cushion or pad)

flush to the top of the flat

plate coupler, centered over the hole.

5. Use a

constant voltage sine wave generator

with a 50

output impedance to supply

the speaker with a 1mW, 1KHz signal to the appropriate connector. For more

information, see “Airman 750/760 Models and Connector” on page 8.

NOTE:

Once the headset/headphone is connected to the constant voltage

sine wave generator, the output voltage can be measured at the sine wave generator

or by the audio analyzer connected to the lab microphone.

FIGURE 5.

Flat Plate Coupler