3

of

12

©

2008 W

544

-

12/08

Mounting the Thermostat

If a single or double gang switch box is used, mount the

thermostat directly to the box.

•

Feed the wiring through the openings in the back of the

thermostat.

•

Use the upper and lower screw holes to fasten the

thermostat to the box.

Remove the Wiring Cover:

To remove the wiring cover:

•

Place a small slot screwdriver or similar tool into the slot

located on the right side of the thermostat.

•

While pushing against the plastic tab, lift off the wiring

cover.

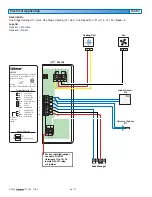

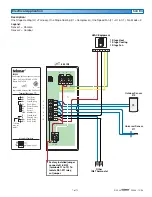

The electrical drawing examples on the following

pages show the 544 in common applications. Choose

the drawing that most accurately depicts the components

in your system and use that drawing as a guide to aid in

wiring your system.

These are only concept drawings, not engineered drawings.

They are not intended to describe a complete system nor

any particular system. It is up to the system designer to

Electrical Drawings

OR

Wiring Symbols

Dry contact switch. Operates a device.

Do not apply power

to these terminals.

Serious control damage will result.

Powered switch. 24 V (ac), switched

output to valve, pump relay etc.

tekmarNet

®

4

Factory jumper.

If a switch box was not used, mount the thermostat directly

to the wall.

•

Feed the wiring through the openings in the back of the

thermostat.

•

Use screws in the upper and lower screw holes to fasten

the thermostat to the wall. At least one of the screws

should enter a wall stud or similar rigid material.

determine the necessary components for and configuration

of the particular system being designed including additional

equipment isolation relays (for loads greater than the

controls specified output ratings) and any safety devices

which in the judgement of the designer are appropriate in

order to properly size, configure and design that system

and to ensure compliance with building and safety code

requirements.

Stud

Thermostat

Base

Terminal

Cover

3

1

/

4

”

(83 mm)

Switch Box

Stud

Wall

Thermostat

Base

Terminal

Cover