5

2

06/06/2016 Rev:2.0.0

English

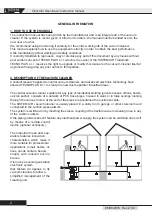

4 - CONSTRUCTION FEATURES

The Industrial Clean Basic dust separators can be used in different contexts, thanks to their versatility

and combination possibilities with the other components of the industrial central vacuum system.

The dust containers are available in two versions with different capacity and can be used in both big or

small industrial contexts.

The choice must be made depending on the total air fl ow of the motors they are combined with and on

the number of users.

Since the industrial dust separators are a component of the installation, it is recommended to make a

defi nitive choice only after carefully evaluating the project globally, considering the needs of use and

the type of installation, but also the other necessary components in order to obtain the most complete

vacuum system.

Motor air

fl ow

MODEL

ARTICLE

Recommended

number of

users Ø 32

Recommended

number of

users Ø 40

Dust

container

capacity l

Filtering

surface

cm

2

Fino a 700

m3/h

BASIC

LT 80

3400.20

4

3

62

24000

Fino a

1200 m3/h

BASIC

LT 160

3400.21

8

4

106

43400

The Industrial Clean Basic dust separators are designed and manufactured in compliance with all the

criteria imposed by the current regulations and European directives while carefully paying attention to

crucial elements like performance, power and operating capacity.

The main technical characteristics are the following:

- Epoxy-powder coated cylindrical body made of metal

- Base coated with shockproof material to protect the unit.

- Metal bin for dust collection (62/106 l capacity) equipped with wheels for a more comfortable handling.

- Dust bag and bag-stretcher for dust collection, to ensure quick and hygienic disposal operations of the

material collected

- Left or right connection possibility both to input pipes (suction) and to exit pipes (motor groups).

- Vacuum-breaker valve to prevent that the motor works in critical conditions.

- Polyester fi lter cartridge with M-class certifi cate, washable in water.

- Metallic fi lter protection to prevent accidental breaks.

- Liquid suction by using the optional accessory.

- Electrostatic material suction, once the grounded metallic pipe network has been carried out.

Summary of Contents for 3400.20

Page 2: ......

Page 93: ...19 5 06 06 2016 Rev 2 0 0 Español ...

Page 94: ...20 06 06 2016 Rev 2 0 0 CENTRAL VACUUM SYSTEMS ByTecnoplus s r l ...

Page 95: ......