IST-2293.EO01.01/C

Istruzione / User’s Manual / Manuel d’utilisation

Pag.5/9

TECNOCONTROL S.r.l. Via Miglioli 47 SEGRATE ( MI )

Tel: 02/26 92 28 90 Fax: 02/21 33 734

Yellow and green Led activates (

0 mA output signal

):

this happens when the “

Cartridge Sensor

” is not working.

First try to perform the procedure of “

Calibration in Air

” as described in the section

“

Test and Calibration > Calibration in

Air

”

then disconnect and connect the unit, finally try to replace a new

“

Cartridge Sensor

”. If the condition is not

change, please replace the unit and/or send it back to the supplier to repair.

All Led activates

only if reed Led be activate by Dip-Switch no.1 set to ON

(

>20 mA output signal

):

this happens when the

“

Cartridge Sensor

” is not working or gas concentration is higher than F.S. (30%vol. O

2

) If there are not any gas leaks

and the condition is not change, please replace the unit and/or send it back to the supplier to repair.

INSTALLATION

The detector must be accurately installed and testing according to the national dispositions in force on the safety of

the plants and installation of electric devices in areas with danger of explosion.

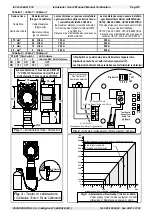

Mounting

: The

fig. 2

shows the instrument size. The unit must be positioned vertically with the sensor downwards.

TS203EO positioning:

It should be fixed at 1.60 m from the floor (the

O

2

gas is lighter as air).

Electrical Connection

(

see fig.2

)

: the maximum distance to install each detector from the Gas Central Unit is show

in the

Table 1

. Normally use a tree wire shielded cable.

The terminals (

+ - S

), are polarized plug-in type, it is necessary to extract them to make the connection.

Note: Dip-Switch should be set with instrument powered off. Dip-Switch 1 settled ON activates ALARM red

Led indication (see Table 2).

Important:

Once installation is completed,

power up the unit, wait about 30 to 60 minutes and then to adjust the

sensor to the environment, only if it is necessary,

carry out the

”

Calibration in Air

”

(see ‘

Test and Calibration

).

COMPATIBILITY WITH OTHER CENTRAL UNITS: In case of a central unit other then Tecnocontrol,

please

verify the max load resistor as shown in

fig. 4

.

The max load resistor is 50 ohm with 12Vdc power supply, while is

400 ohm with 24Vdc power supply.

We suggest using 24Vdc power supply.

WARNING

Average life

: In clean air and in normal working condition the

sensor's life is

about 2 years.

After this period the

yellow Led “

FAULT

” flashes every 4 seconds, is necessary replacing the “

Cartridge Sensor

”.

Periodical testing

: we advise to carry out working tests every 6 or 12 months. as explained in chapter “

Tests and

Calibration

”.

Note:

the detector is not able to detect Oxygen gas occurring outside the room where it is installed.

Sensor operating limits:

the electrochemical cell, in any case, should not be exposed to temperatures lower than

-40°C or higher than 60 °C. The electrochemical cell can be damaged, if it is exposed to concentrations over con-

centration of 30 % O

2

. If this condition occurs, we suggest replacing the “

Cartridge Sensor

”.

Safety:

Oxygen sensors contain a small quantity potassium acetate solution which is corrosive. Normally this ma-

terial would only leak out as a result of either mechanical damage or an incorrect instrument use beyond the limits

of its operational functioning. These sensors also contain small amounts of lead, lead oxide, platinum, silver, car-

bon and antimony. If the user comes into contact with the oxygen sensor contents the affected area should be

washed with a copious supply of water.

Cross sensitivity to other gases:

The electrochemical cell employed has a good resistance towards products

such as sprays, detergents, ammonia, glues and paints.

However, in case of products containing substances in

great quantity, these could interfere with the Sensor and cause false alarms.

We recommend ventilating the room

when products like these are used. Volatile organic solvents in great quantity cause false alarms, and then the cell

needs one or more hours in clean air to recover the normal sensitivity conditions.

TEST and CALIBRATION

PAY ATTENTION

: This procedure has to be made with extreme attention and by authorized and trained people;

because starting this procedure it will increase mA output causing the activation of connected alarm devices.

Operation Check, Calibration in Air and Fine mA ADJ Output

:

are different code protected functions. To access

these functions is necessary to insert the relevant “

Code

" through the keys F1s and F2. To have the key pressure

recognized, hold pressing it for around a second (

until the Green LED doesn't switch off for a moment

). Then the next key

can be pressed. In case of error all it takes is waiting around 10 seconds and the sequence is automatically era-

sed. The

Calibration Check

is a function code free.

Calibration Kit, Sample Gas Bottles

(

for Calibration Check

) please, only using a mixture

16% volume Oxygen (O

2

) in nitrogen

You can use either the disposable cylinder, with adjust valve or

the high pressure ones with reduction gear. Is also

necessary to use

the calibration kit Tecnocontrol mod. TC011.

“INSTRUMENT OPERATION CHECK” (

Check Code

: F2, F2, F1, F1):

this function allows to effect a functional test

of the detector. After having inserted the "

Code Test

", all Led are switched off. Then Led will switch on in sequence,

from the yellow up to the red. At the end all the Led will remain lighted for around 5 seconds, then the detector re-

turns at the conditions of normal operation. It is advisable to perform this operation every 12 months according to

the use.

Note

: this function is not working if the red Led have already turned on.

“CALIBRATION IN AIR” (

Calibration Code

: F2, F2, F2, F1, F2, F1):

this function allows completely recalibrate the

sensor at 20,9%volume in clean air. This procedure when it is launched, will automatically until the end.

Warning

:

to guarantee that no errors of elaboration happen, the possibility exists that during the Calibration the yel-

low Led switch off every 8 seconds, in this case interrupt the procedure, switch off and switch on the instrument and

repeat the Calibration. If condition persists it will be necessary to send the detector to the supplier for the reparation.