Issue/Rev. 0.3 (8/02)

MN02004 • 5

Section 2 – Service (continued)

If thrust washer shows signs of wear but is not

cracked, turn washer over.

• In some of the older turbine meter designs, it will

be necessary to apply a small amount of heat to

the stator around the thrust washer area to re

move the washer.

• On models after serial number 229T, the thrust

washer is secured in place with a small amount

of Locktite No. 72-41. This can also be removed

by applying a small amount of heat around the

washer. The washer can then be turned over

for reuse. If the new bearing surface shows

evidence of Locktite (yellowish color), it can

be removed with acetone.

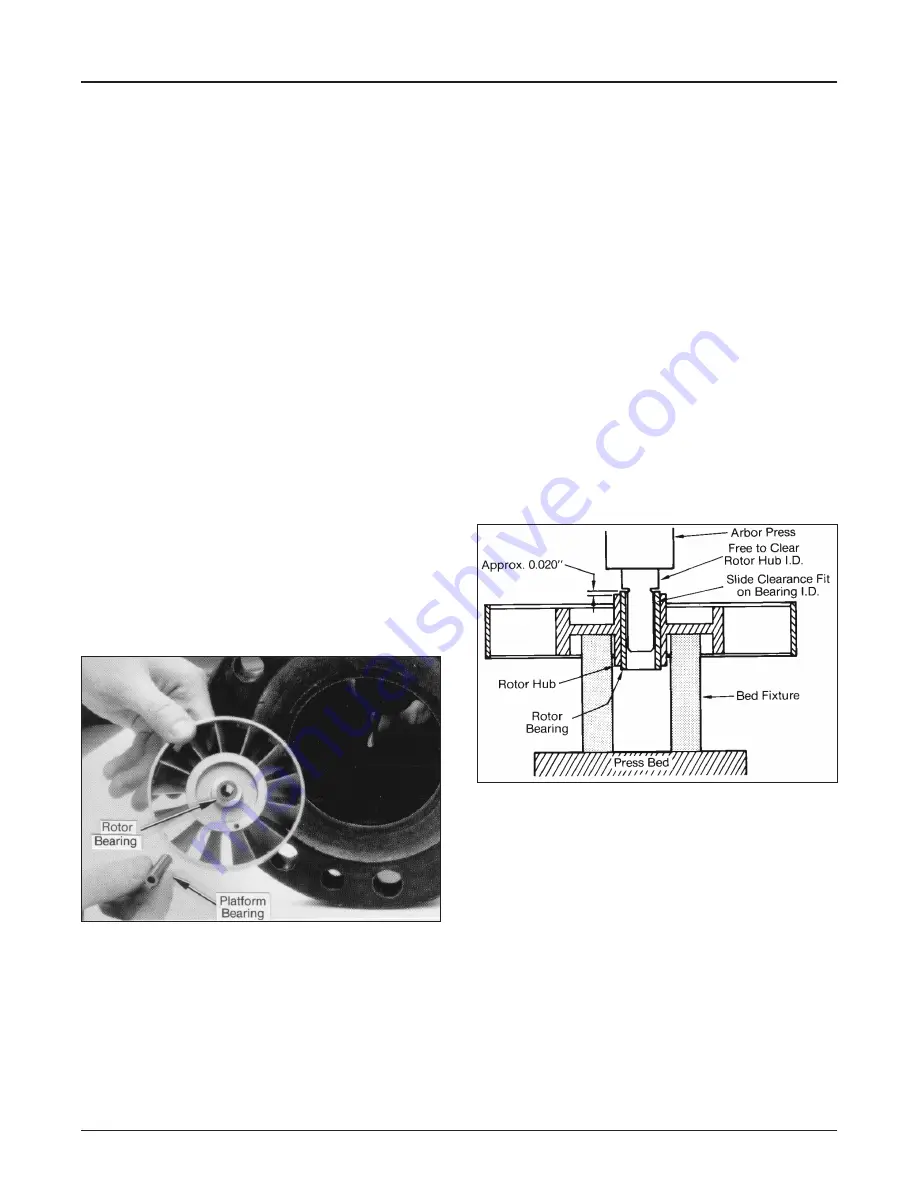

10. Remove rotor and platform bearings, Figure 11,

using extreme care that the platform bearing is

not permitted to fall from the rotor since, due to

the brittleness of the bearing, a fall could result in

severe damage. Inspect outside surface of bearing

for grooves, chipping, roughness, and cracks, as

well as cracks in end surfaces.

When removing the rotor from a bidirectional

turbine meter, it is necessary to remove the

downstream deflector ring. Remove the set

screw and slide the ring out. When reinserted,

the ring must be relocated exactly in its former

position as the ring properly positions the

downstream stator in relation to the upstream

stator.

Figure 11

Inspect inside surface and end surfaces of rotor

bearing for same defects as for platform bearing.

If bearing surfaces show no defects, the bearing

will be suitable for reuse in most cases.

•

Bearing wear is minimal and bearing

replacement is usually required only due

to damaged surfaces.

11. Should rotor bearing require replacing, it is

suggested that rotor assembly be returned to

Measurement Solutions for rework. See “Return

Procedures,” Page 2.

Rotor bearing replacement can be done in the field

by the following repair procedure.

a. With proper tool and fixture, Figure 12, the

old rotor bearing may be forced out of the

rotor hub with an arbor press. Care must be

taken in the selection of tool and fixture to

insure a “straight line” or axial press only.

Push the bearing out with a smooth, steady

motion.

b. The new bearing may be installed with the

same equipment used to remove the old

bearing. Center the bearing carefully in line

with the hub bore before pressing. The

bearing material has been selected for its

hardness and wear characteristics, but may

be chipped or broken if mistreated. Press the

bearing into the rotor hub to achieve equal

protrusion within 0.005" from both hub faces.

Figure 12

12. Remove upstream stator with shaft and inspect

as described in Step 9. On most unidirectional

models, holes are in nut end of stator (Figure 13).

In some bidirectional turbine meters, two

downstream stators are used. Therefore, the

holes will be located as shown in Figure 10.

13. For a unidirectional turbine meter, it is not

necessary to remove deflector ring in order to

service meter internals. If ring is removed, it must

be relocated exactly in its former position when

reinserted as ring properly positions upstream

stator in relation to down-stream stator. If

necessary to remove, remove set screw and

slide ring out from upstream end of meter,

Figure 14.