EU – 401N User’s manual v 1.1.3

-

8

-

IV.

Collector overheats

This submenu shows a list of collector overheats (instances of too high temperature detected by the

collector sensor). The user may view:

- date of the overheat incident

- time

- duration

- reading from collector sensor

V.

Power failures

This submenu shows a list of power failures registered by the controller. The user may view:

- date

- time

- duration

V.a)

Backlight

This parameter is used to adjust the screen brightness. The screen brightness changes after a few

seconds of inactivity.

V.b)

Display contrast

This parameter is used to adjust the display contrast.

V.c)

Language

This option is used to select the language version of the controller menu.

V.d)

Information

Once this option has been selected, the display shows the controller manufacturer’s logo and current

software version.

V.e)

Factory settings

This function is used to restore factory settings saved previously in the service menu.

IV.

Service menu

In order to enter the service menu, select SERVICE MENU, enter the code using plus and minus: 0112

and confirm by pressing MENU. In order to return to the main screen view (leave the service menu),

press EXIT a few times or wait about 30 seconds ( the controller will leave the service menu

automatically).

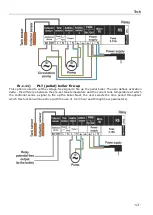

A block diagram of the service menu is presented below.

The EU-401N controller may support different heating installation schemes and selecting a different

scheme results in changes in the service menu layout. Additional parameters are marked with * in the

following block diagram.