2- 5

EM1-33043D

2. SPECIFICATIONS

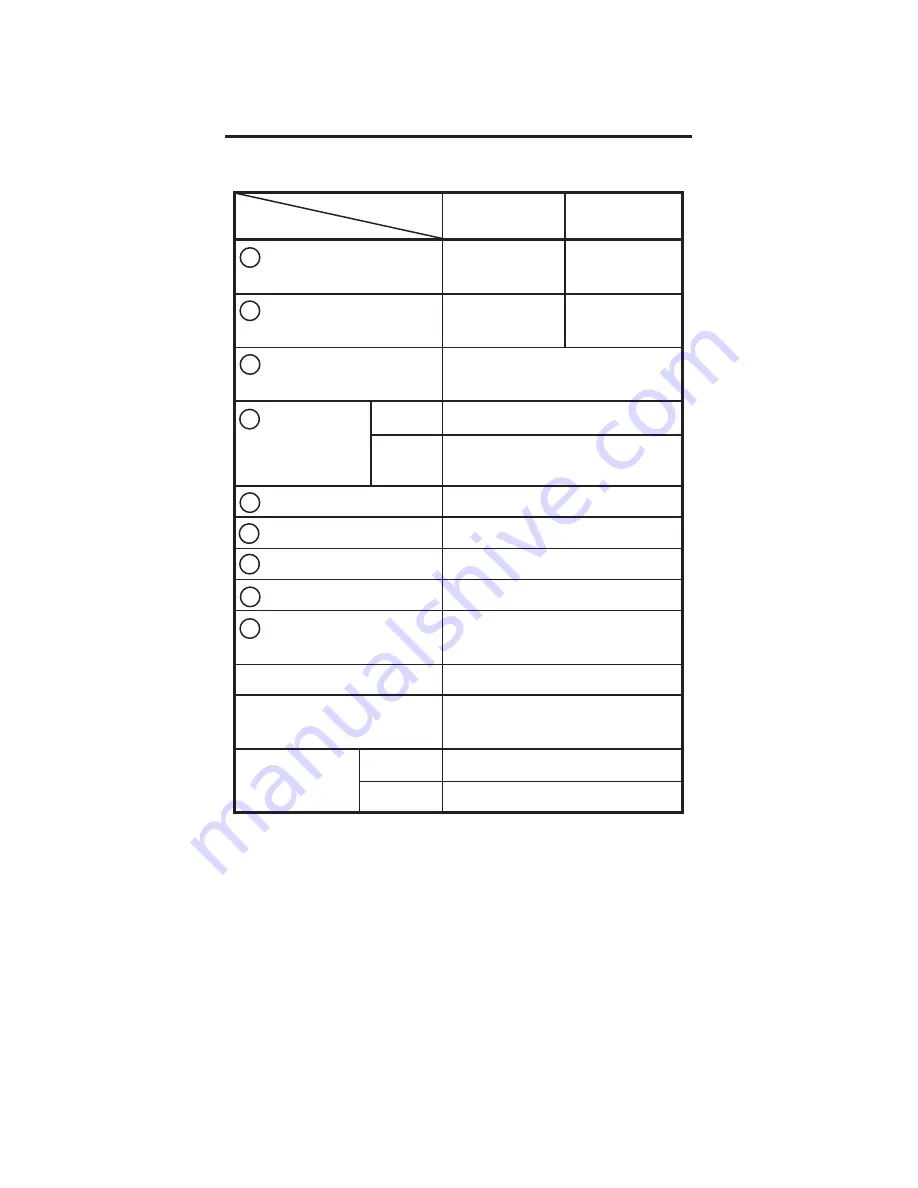

2.5 MEDIA

Issue mode

Item

Label/Receipt

10.0 ~ 167.0

13.0 ~ 67.0

Pitch

Label/Receipt

7.0 ~ 160.0

10.0 ~ 60.0

length

Width including

34, 37, 40, 43, 46, 49,

backing paper

52, 55

±

0.5

Media width Label

31.0 ~ 52.0

Receipt 34, 37, 40, 43, 46, 49

52, 55

±

0.5

Gap length

3.0 ~ 7.0

Black mark length

3.0 ~ 7.0

Effective print width

~ 48.0

Effective print length

7.0 ~ 160.0

Margin

1.0 (gap = 7 mm) ~

5.0 (gap = 3 mm)

Outer roll diameter

ø34 (Max.)

Roll way

The print side facing

inside

Thickness

Label

111

µ

m

Receipt

65

µ

m

Strip mode

Batch mode

C

B

A

D

E

F

G

H

I

(Unit: mm)

NOTE: Do not use media other than the above

to ensure print quality and print head life.