ENGLISH VERSION EM1-33038D

8. LOADING THE MEDIA

8-1

8. LOADING THE MEDIA

EM1-33039E

8. LOADING THE MEDIA

3.

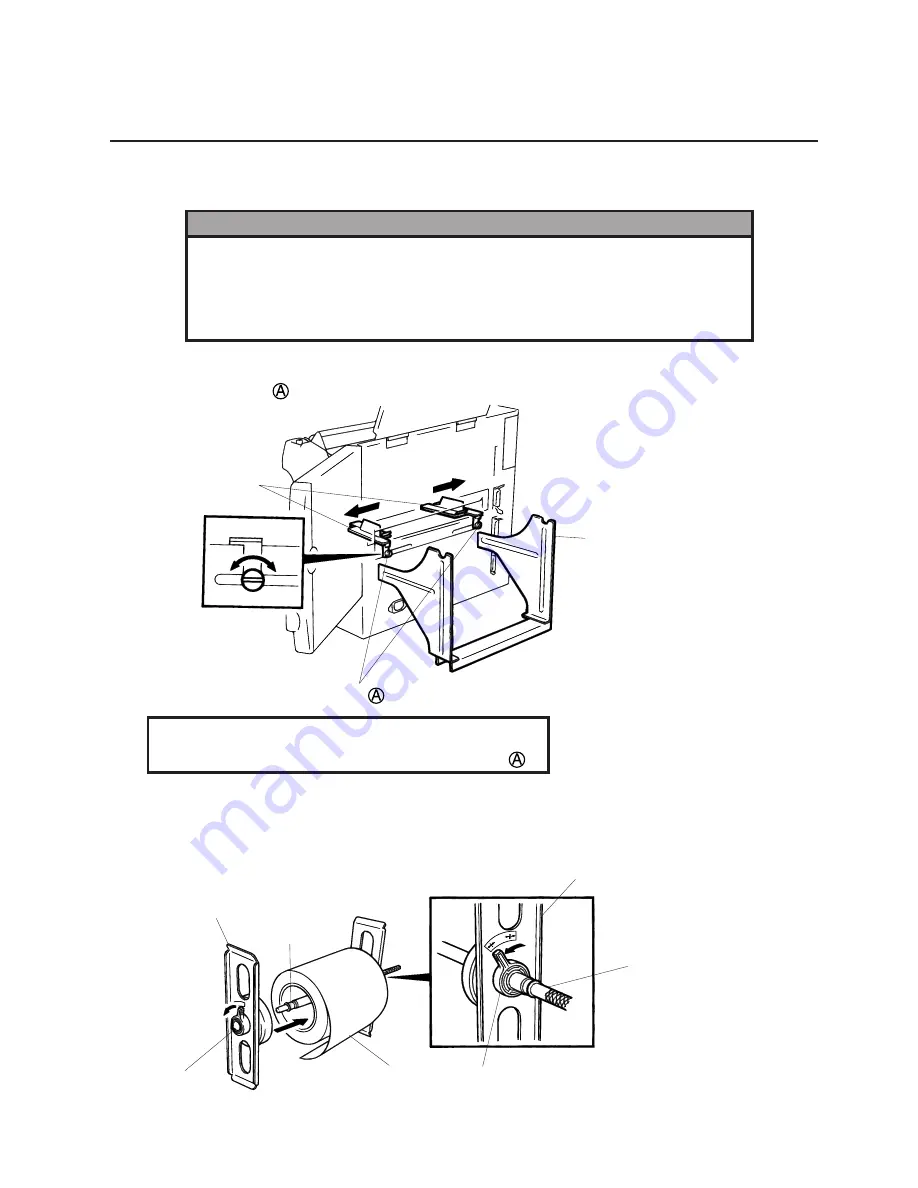

Lock the Media Holder securely with the Lock Lever.

4.

Pass the Holder Shaft through the Media, then set one of the Media Holders and lock it securely with

the Lock Lever.

Fig. 8-2

Fig. 8-1

Holder Stand

Media Guides

Screw

Media Holder

Holder Shaft

Media Holder

Holder Shaft

Lock Lever

Media

Lock Lever

Release Lock

CAUTION:

DO NOT MOVE the Media Guides using the screw

.

WARNING!

1. Do not touch moving parts. To reduce the risk that fingers, jewelry, clothing,

etc., be drawn into the moving parts, push the switch in the “OFF” position to

stop movement.

2. To avoid injury, be careful not to catch or jam your fingers while opening

or closing the cover.

1.

Install the holder stand on the rear of the printer.

2.

Loosen the screw

and slide the media guides outside.

Summary of Contents for B-872-QQ

Page 1: ...TEC Thermal Printer B 870 SERIES Owner s Manual ...

Page 33: ......

Page 34: ...PRINTED IN JAPAN EM1 33039E E ...