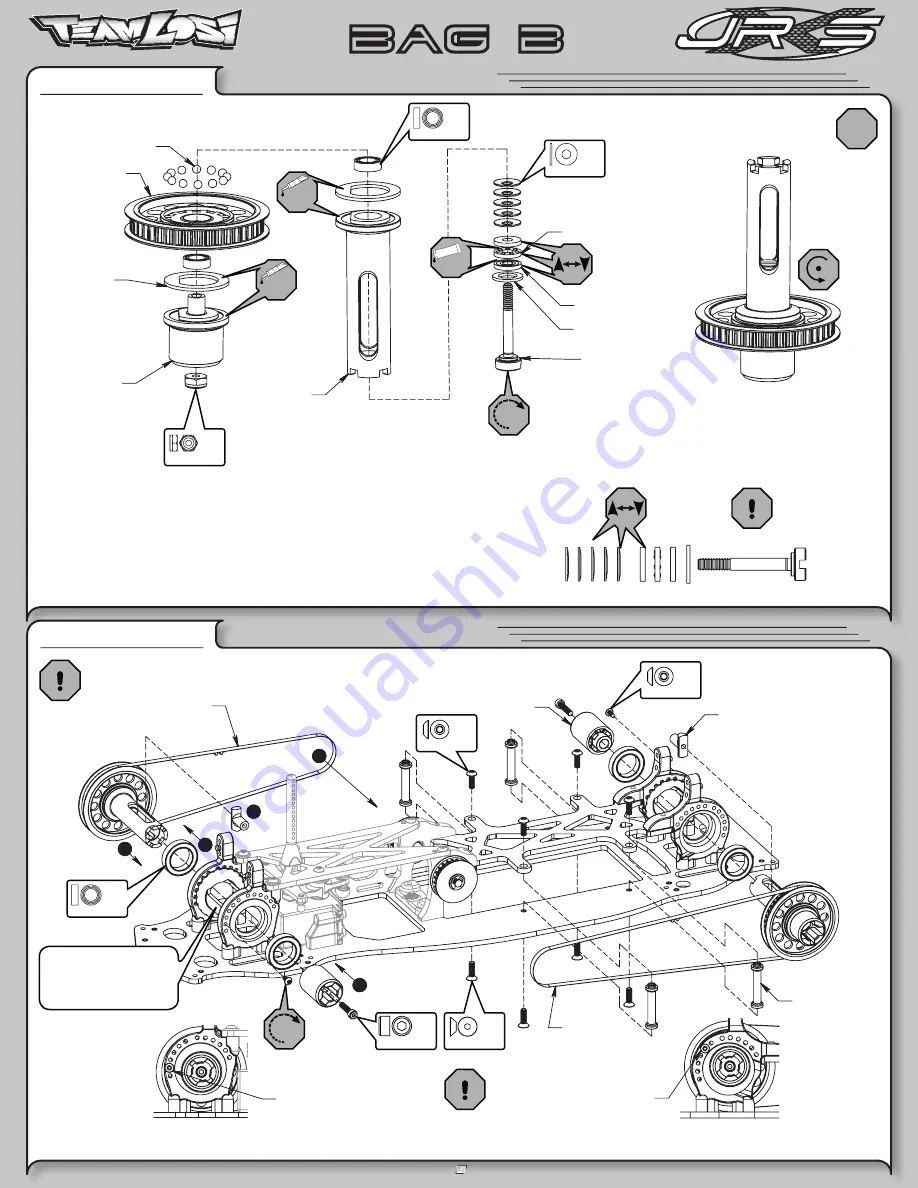

5

A3018

Thrust Washer

Diff Tube

A3315

Diff Screw

A3078

Foam Diff Seal

A3078

A3018

Caged Thrust Bearing

COMPLETED DIFFERENTIAL

A6951

A3070

Diff Pulley, 42T

A3211

Diff Ring

Carbide

3/32" Diff Ball,

A3310

Diff Outdrive,

Male

3

1

2

4

INITIAL REAR BELT

TENSION SETTING FOR

DIFF IN HIGH POSITION

(SEE SETUP GUIDE FOR ACENTRIC SETTING)

A3310

Diff Outdrive,

Diff T-Nut

A3312

5

(Grey)

Rear Drive Belt

A3302

(White)

Front Drive Belt

A3301

Female

A4314

Chassis Support

Post

INITIAL FRONT BELT

TENSION SETTING FOR

DIFF IN LOW POSITION

(SEE SETUP GUIDE FOR ACENTRIC SETTING)

DO NOT PINCH BELTS

4-40 x 5/16”

x4

4-40 x 3/8”

x4

It may be necessary to

temporarily rotate the Diff

Acentric into the HIGH

position to install the Diff.

Apply a small amount of Clear Diff Grease to the Diff Outdrive and the Diff Tube

before installing the Diff Ring.

Apply enough Clear Diff Grease to the top side of the Diff Rings, or to both sides of

recessed Ball section in the Diff Pulley (after Diff Balls are installed) to cover the

Diff Balls when the Diff is assembled.

Assemble the Diff and tighten until some resistance is felt, see the Final Checklist

for fi nal Diff adjustment procedures.

•

•

•

CAUTION!

Some Thrust Bearing assemblies

come bound with a small wire. This wire must be

removed before installing the Thrust Bearing.

BAG B

Differential Assembly

STEP B-03

Differential Installation

STEP B-04

L 4-40 x 1/4”

x1

5mm x 8mm

x2

GREASE

CLEAR

GREASE

CLEAR

GREASE

See Checklist, p.20

Belleville

x5

1

2

3

4

5

2-56 x 1/4”

x2

1/2” x 3/4”

x4

x2

4-40 x 1/2”

x2