Step 15

Step 10

Step 6

Step 18

Step 14

6

7

8

9

10

11

12

13

14

15

16

17

18

19

CAUTION:

The exposed PCB is ESD

sensitive and static discharge can damage

the electronics. Minimize handling of the

exposed PCB.

Use your fingernail or a flathead screwdriver to

press on the tab on the motor control cable

connector (as shown in the image to the right).

Carefully pull the connector up to disconnect it

from its socket in the drone.

REPLACEMENT

INSTRUCTIONS

(CONTINUED)

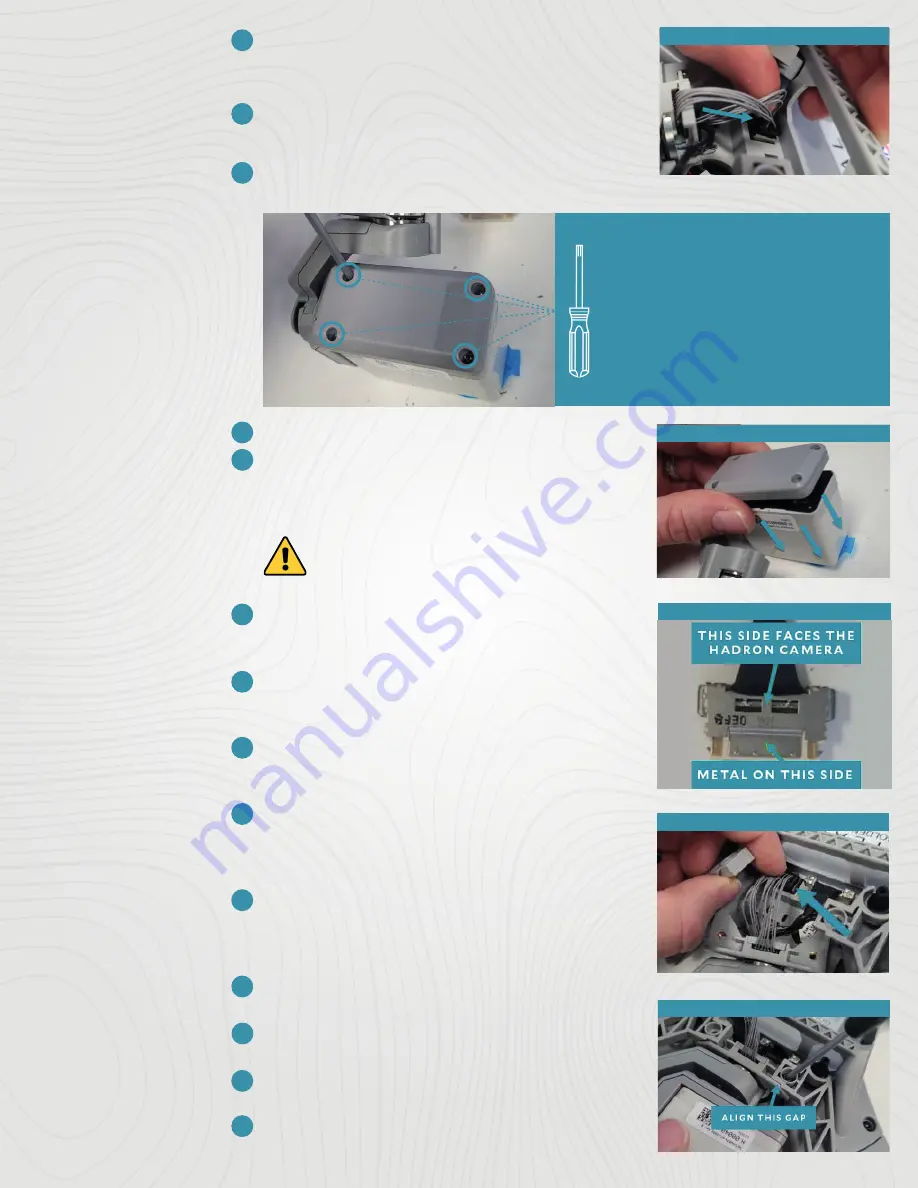

Use a T5 Torx screwdriver to remove the

four (4) M1.6 x 4mm screws from the back of the Hadron camera.

Set the screws aside for re-use.

Disconnect the Hadron camera from the gimbal

by carefully pulling it away from the gimbal (as

shown in the image to the right).

Tools Needed:

One (1) T5 Torx Screwdriver

Removal:

Four (4) M1.6 x 4mm Screws

Check that the gasket around the PCB on the

Hadron camera is properly aligned and adjust if

needed.

Push the Hadron camera onto the gimbal. Press

firmly until you feel the connector “click” into

place.

Use a T5 Torx screwdriver to secure the four (4)

M1.6 x 4mm screws in the back of the Hadron

camera.

Connect the camera data cable connector to

the mating socket in the drone so that the side

of the cable as shown in the image to the right

is facing towards the front of the drone.

Connect the gimbal motor cable connector to

the mating socket in the drone so that the tab

on the connector is facing toward the front of

the drone (as shown in the image to the right).

Align the threaded inserts on the gimbal under

the holes on the gimbal brackets.

Place the two (2) M3 x 8mm screws into the

holes on the gimbal brackets.

Align the gaps (as shown in the image to the

right).

Use a Torx T8 screwdriver to tighten the

screws to 0.6 N*m (0.44 ft-lbs).

03

© 2022 Teal Drones, Inc.

SUP-00005, REV A