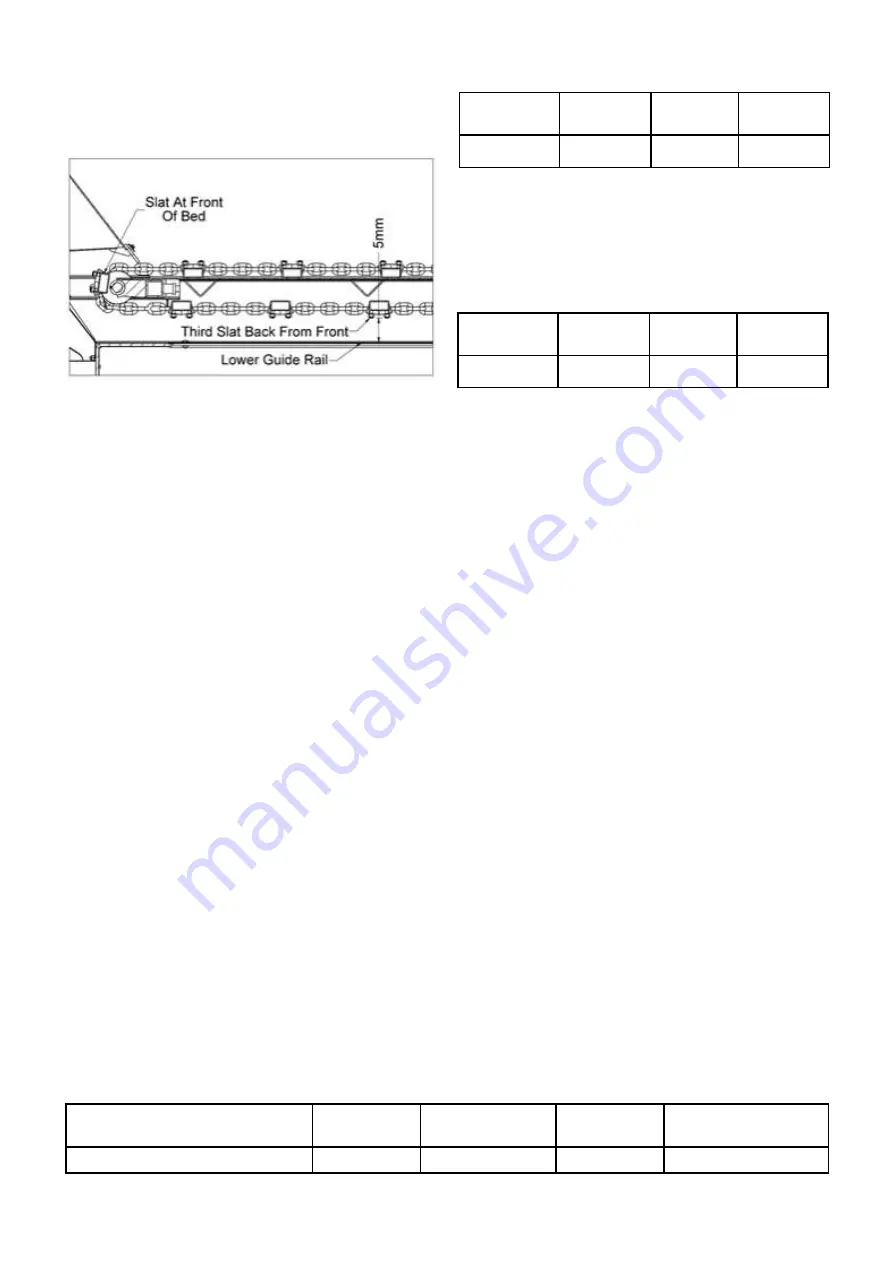

the machine approximately level with the centre of the

front cross shaft. The third slat underneath should be

5mm clear of the lower guide rail. Figure 4 illustrates

this. Check the tension on both the left and right hand

sides.

Figure 4 Correct bed conveyor tension

To increase tension, screw the tensioners forwards

and lock in position using the locking nuts. Check the

tension on both the left and right hand sides after

adjusting.

After a long period of use, the threaded screw

adjusters may reach the end of their travel. In this

instance, to gain more tension the conveyor will need

to be shortened. This is done by removing two links

from one of the chain sections from the same position

on both the left and right hand sides of the conveyor.

After re-bolting the shortened chain sections back into

the conveyor, re tension the threaded adjusters.

BEATERS

Regularly check the condition of the beaters and

repair any damage immediately. Severely worn tips

will adversely affect the spread pattern, reduce the

shredding of material and increase the power

requirement. Worn tips should be reversed or replaced

as necessary.

PTO DRIVELINE

The PTO shafts should be checked regularly and any

broken or damaged guards replaced. All joints should

be checked and replaced if damaged. Replacement

PTO parts including guards are readily available.

The optional ratchet clutch is totally enclosed and

does not require routine maintenance other than

lubrication.

AXLES, WHEELS & TYRES

The axle retaining bolts should have their torque

checked after the first 10 hour’s use and then every 50

hours. Table 1 gives the correct torque setting.

Table 1. Axle retaining nut and bolt torque setting

After the first hour’s use and then every 50 hours,

check the wheel nuts for tightness. If allowed to work

loose, the rims and wheel studs will become damaged

and it will be impossible to keep the wheel nuts tight.

The wheel nut torque setting is given in Table 2.

Table 2. Wheel nut torque setting

The removal, repair, refitting and inflation of a tyre can

cause accidents and this operation should be carried

out by a specialist tyre repairer.

Tyre inflation should always be carried out in a cage

with all personnel stood to one side, never in front.

When removing and refitting the wheels, ensure that

the machine is securely supported with the use of

correctly rated axle stands positioned on a level firm

surface. When the wheels are removed and

transported, they should be securely restrained and

checked for:

1. Damage to stud holes in the flange

2. Severe rust damage

The maximum inflation pressure for the standard tyre

size is given in Table 3.

AIR BRAKE SYSTEM

If the spreader is fitted with air brakes the air reservoir

requires draining daily, This is done by pulling down

on the ring at the base of the reservoir.

There is a manual load sensing valve fitted which

provides three levels of braking aggressiveness. The

setting is adjusted by rotating the lever fitted to the

valve. The least aggressive setting is suitable for

towing the spreader when empty. The most

aggressive setting should be used only when the

spreader is being towed laden.

A manual shunt valve is fitted in the air brake circuit.

When the button is pressed, the shunt valve releases

air pressure from the system so that the spreader can

be moved using a tractor fitted only with hydraulic

trailer brakes.

Socket Size

(mm)

Thread

(mm)

Torque

(lb/ft)

Torque

(Nm)

32

M22 x 1.5

332

450

Table 3. The maximum inflation pressure for the standard tyre size offered

Size

Ply Rating

Outside Diameter

(mm)

Width

(mm)

Max Inflation

Pressure

580/70 R38

R

1817

577

3.4 Bar (49 psi)

6

Socket Size

(mm)

Thread

(mm)

Torque

(lb/ft)

Torque

(Nm)

36

M24 x 3.0

332

450

Summary of Contents for TITAN 10

Page 1: ... _ _ _ _ _ _ _ _ _ _ _ _ ...

Page 50: ...47 NOTES ...

Page 51: ...48 WIRING DIAGRAM LED LIGHTS WIRING DIAGRAM TRACTOR LEAD ...

Page 52: ......